Dune Buggy Body: Everything You Need to Know

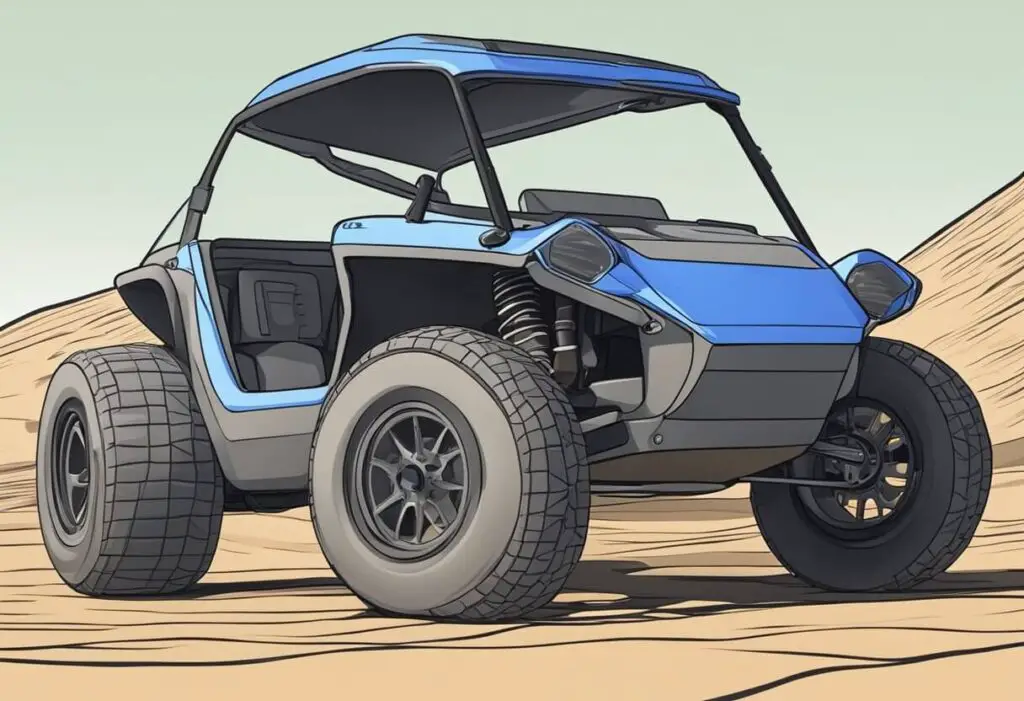

Cruising through sand dunes in a lightweight off-road vehicle – the dream of dune buggy enthusiasts everywhere. But what actually makes these unique vehicles so well-suited for rugged terrain? The key lies in the dune buggy body. So how exactly is a dune buggy body designed to handle the demands of off-road driving?

In short, dune buggy bodies are constructed from durable yet lightweight materials like fiberglass, creatively shaped for aerodynamics, and engineered for optimal weight distribution. This allows them to tackle sandy hills and uneven trails with ease.

In this post, we’ll explore the intricacies of dune buggy body construction. We’ll look at the materials and manufacturing processes used, types of bodies available, how they attach to the chassis, options for customization, key maintenance and repair tips, safety considerations, and regulations around street legality. Let’s jump in and unravel the secrets behind the versatile dune buggy body!

Dune Buggy Body Basics

Materials and Composition

Dune buggy bodies are typically made from fiberglass, which is a strong and lightweight material that is ideal for off-road vehicles. Fiberglass is a composite material made from a combination of glass fibers and resin. The glass fibers provide strength and rigidity, while the resin acts as a binder to hold the fibers together.

In addition to fiberglass, some dune buggy bodies may also be made from other materials such as aluminum or steel. However, these materials are less common due to their weight and cost.

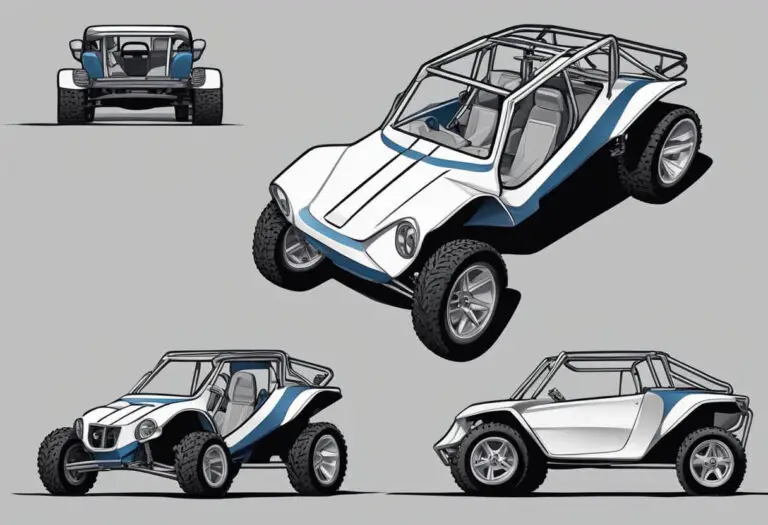

Design Principles

Dune buggy bodies are designed to be aerodynamic and lightweight, which helps to improve their performance off-road. The body shape is typically sleek and streamlined, with a low profile to reduce wind resistance.

The design of the body also plays a role in the weight distribution of the vehicle. A well-designed dune buggy body will distribute the weight evenly between the front and rear axles, which helps to improve traction and handling.

Other design features of dune buggy bodies may include roll cages, which provide added safety in the event of a rollover, and removable panels for easy access to the engine and other components.

Overall, the design and composition of a dune buggy body are essential factors that contribute to the performance and safety of the vehicle. By choosing the right materials and design principles, dune buggy enthusiasts can create a vehicle that is both fun to drive and safe to operate.

Types of Dune Buggy Bodies

Fiberglass Bodies

Fiberglass is the most common material used for dune buggy bodies. It is lightweight, durable, and easy to mold into various shapes. There are several types of fiberglass dune buggy bodies available in the market.

One popular type is the Mini T, which is a two-seater dune buggy body made of fiberglass. It has a T-model dune buggy style and is similar to a miniature T-type truck. Another well-known brand is the Meyers Manx, which designs and sells high-quality fiberglass dune buggies for the off-road market. The company’s design style is an enhancement of the traditional body shape, offering quick body integrations in concert with vintage Volkswagen chassis. Berrien Body is another manufacturer that builds fiberglass half-body styles for the off-road market.

Metal Bodies

While fiberglass is the most popular material for dune buggy bodies, metal bodies are also available. Metal bodies are heavier and more durable than fiberglass bodies. They are also more expensive and harder to shape.

One example of a metal dune buggy body is the Volkswagen Beetle, which was used as the base for the original dune buggies. The Beetle’s metal body was cut and modified to create a lightweight, off-road vehicle.

Custom Bodies

Custom dune buggy bodies are also available for those who want a unique look. Custom bodies can be made from a variety of materials, including wood, plastic, and carbon fiber.

One example of a custom dune buggy body is the Bandit Dune Buggy, which offers a fiberglass body kit that fits on a full-length VW chassis. The kit includes a full-length body, hood, and fenders. Another example is the Bremen Motorsports of Indian, which is known for the Citation dune buggy body and also made the full-length Maxi Taxi.

In conclusion, there are several types of dune buggy bodies available in the market. Fiberglass bodies are the most common, but metal and custom bodies are also available. Each type has its advantages and disadvantages, and the choice depends on the individual’s preference and budget.

Manufacturing Processes

Molding Techniques

The most common molding technique used in the production of dune buggy bodies is fiberglass molding. Fiberglass molding is a process that involves the use of a mold to create a fiberglass part. A mold is created from a pattern or plug, which is a model of the final part. The mold is then coated with a release agent, and layers of fiberglass mat and resin are applied to the mold. The layers of fiberglass mat and resin are then allowed to cure, and the resulting part is removed from the mold.

Another molding technique used in the production of dune buggy bodies is vacuum bagging. Vacuum bagging is a process that involves the use of a vacuum to compress layers of fiberglass mat and resin onto a mold. The mold is first coated with a release agent, and then layers of fiberglass mat and resin are applied. A vacuum bag is then placed over the mold and sealed around the edges. The vacuum is then turned on, which compresses the layers of fiberglass mat and resin onto the mold. The layers are then allowed to cure, and the resulting part is removed from the mold.

Fabrication Methods

In addition to molding techniques, there are also a variety of fabrication methods used in the production of dune buggy bodies. One common fabrication method is welding. Welding involves the use of heat and pressure to join two pieces of metal together. This technique is often used to create the frame of the dune buggy body.

Another common fabrication method used in the production of dune buggy bodies is cutting and shaping. This technique involves the use of cutting tools such as saws and grinders to shape and cut the body panels. Once the panels have been cut and shaped, they can be welded together to form the final body.

Overall, the manufacturing processes used in the production of dune buggy bodies are varied and complex. The most common techniques used include fiberglass molding, vacuum bagging, welding, and cutting and shaping. These techniques are used to create high-quality, durable dune buggy bodies that are able to withstand the rigors of off-road driving.

Assembly and Installation

Chassis Integration

The first step in assembling and installing a dune buggy body is to integrate it with the chassis. This involves ensuring that the body fits securely onto the chassis and that all mounting points are aligned properly. Before starting the integration process, it is important to ensure that the chassis is in good condition and that all necessary repairs and modifications have been made.

One common method of chassis integration is to use a bolt-on kit. These kits typically include all the necessary hardware and instructions for mounting the body onto the chassis. It is important to follow the instructions carefully and ensure that all bolts are tightened to the correct torque specifications.

Another method of chassis integration is to weld the body directly onto the chassis. This method requires more skill and experience, but can result in a more secure and permanent attachment.

Attachment Methods

Once the body is integrated with the chassis, it is important to choose the right attachment method to ensure that the body remains securely in place. There are several different attachment methods available, including:

- Bolts: Bolts are a simple and effective attachment method that can be used to secure the body to the chassis. It is important to use high-quality bolts and ensure that they are tightened to the correct torque specifications.

- Clamps: Clamps can be used to secure the body to the chassis without the need for drilling or welding. They are a quick and easy attachment method, but may not be as secure as bolts or welding.

- Welding: Welding is the most secure attachment method and can provide a permanent bond between the body and the chassis. However, it requires skill and experience to ensure that the welds are strong and durable.

It is important to choose the right attachment method based on the specific needs of the dune buggy and the skill level of the builder. Regardless of the attachment method chosen, it is important to ensure that the body is securely attached to the chassis to ensure safe and reliable operation.

Customization and Modification

When it comes to dune buggy customization and modification, the possibilities are endless. From painting and graphics to body trimming and accessories, there are many ways to make your dune buggy stand out and reflect your personal style.

Painting and Graphics

One of the easiest and most popular ways to customize a dune buggy is through painting and graphics. A fresh coat of paint can give your buggy a whole new look and feel. You can choose from a variety of colors and finishes, including metallic, matte, and glossy.

Graphics can also be added to the body of the dune buggy to make it stand out. You can choose from pre-made graphics or create your own custom design. Graphics can be added to the hood, doors, and even the sides of the buggy.

Body Trimming and Accessories

Body trimming and accessories can also be added to customize your dune buggy. Trimming the body can help reduce weight and improve performance. Fiberglass body kits are a popular option for dune buggies because they are lightweight and durable.

Accessories such as grab handles and footrests can be added to the framework of the dune buggy to give passengers something to hold onto during the ride. Roll cages are also recommended to keep passengers safe during high-speed rides.

In conclusion, dune buggy customization and modification is a great way to make your buggy stand out and reflect your personal style. From painting and graphics to body trimming and accessories, there are many ways to make your dune buggy unique and one-of-a-kind.

Maintenance and Repair

Regular Maintenance

Regular maintenance of a dune buggy body is important to keep it in good condition and prevent major repairs. Here are some tips for maintaining a dune buggy body:

- Wash the body regularly with soap and water to remove dirt and debris.

- Check for any cracks or holes in the body and repair them immediately to prevent further damage.

- Apply a coat of wax to protect the body from the elements and keep it looking shiny.

Repair Techniques

Even with regular maintenance, dune buggy bodies may require repairs from time to time. Here are some repair techniques that can be used:

- Bondo Glass is a great product for repairing holes, cracks, and other damage to the dune buggy chassis. It is a reinforced filler that can be sanded and painted to match the original body.

- Fiberglass repair is another option for repairing cracks and holes in the body. The damaged area is ground down, and new fiberglass is laid over the damaged area and allowed to cure.

- Regularly inspect the body for any signs of damage, such as cracks or holes. If any damage is found, it should be repaired immediately to prevent further damage.

Safety Considerations

When it comes to dune buggy body, safety should be the top priority. There are two main safety considerations to keep in mind: structural integrity and impact resistance.

Structural Integrity

The structural integrity of a dune buggy body is crucial for safety. A well-built body will help prevent the vehicle from collapsing or breaking apart in the event of a crash or rollover. It is important to ensure that the body is made from high-quality materials and is properly reinforced.

Impact Resistance

Another important safety consideration is impact resistance. A dune buggy body should be able to withstand impacts from rocks, trees, and other obstacles that may be encountered while off-roading. This is especially important for the front and rear sections of the body, which are most likely to be impacted.

To ensure maximum impact resistance, some dune buggy bodies are made from materials such as fiberglass or carbon fiber, which are lightweight yet strong. Additionally, some manufacturers offer body kits that include reinforced bumpers and skid plates for added protection.

It is also important to note that proper safety equipment should always be worn while operating a dune buggy, including a safety-certified helmet and seat belt. Following these safety considerations will help ensure a safe and enjoyable off-roading experience.

Regulations and Compliance

Dune buggies are regulated by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA). These agencies set standards for vehicle safety and emissions, and all vehicles, including dune buggies, must meet these standards to be considered street legal.

Vehicle Standards

To meet the federal safety standards, dune buggies must have a factory-built body or a body that is constructed to resemble a factory-built body. The vehicle must have a 17-digit vehicle identification number (VIN) that is assigned by the manufacturer. Additionally, dune buggies must have all required lighting, such as headlights, taillights, and turn signals.

Most states require two working headlights that illuminate at least 500 feet ahead. They must be between 22-54 inches from the ground. Dune buggies must also have taillights, stoplights, turn signals, mirrors, and seatbelts. In some cases, windshield wipers are also required.

Environmental Regulations

Dune buggies must also meet the environmental regulations set by the EPA. This includes meeting emissions standards and having a catalytic converter installed. It is important to note that emissions standards vary by state, and it is important to check the requirements in your area to ensure that your vehicle is compliant.

In summary, to make a dune buggy street legal, it must meet all federal safety standards and environmental regulations. This includes having a factory-built body or a body that resembles a factory-built body, a 17-digit VIN, and all required lighting and safety features. It is important to check the requirements in your state to ensure compliance with both federal and state regulations.

Market Trends and Consumer Preferences

Dune buggies have been a popular off-road vehicle for decades, and their popularity continues to grow. As consumer preferences shift towards more environmentally friendly options, electric dune buggies are becoming increasingly popular in the market. Meyers Manx, a well-known dune buggy manufacturer, has recently released an electric version of their classic buggy.

In addition to electric options, consumers are also looking for dune buggies with customizable features. Adjustable seats, LED headlights, and a variety of colors are among the most popular features that consumers look for in a dune buggy. Manufacturers are responding to this trend by offering more options for customization.

When it comes to dune buggy bodies, fiberglass is the most common material used. Fiberglass is lightweight and durable, making it an ideal material for off-road vehicles. Consumers prefer fiberglass bodies because they are easy to repair and maintain.

Overall, the market trends for dune buggies are shifting towards more environmentally friendly options and customizable features. Manufacturers are responding to these trends by offering more options for customization and electric options. Fiberglass bodies remain the most popular choice among consumers due to their durability and ease of maintenance.