Fiberglass Dune Buggy Body: Benefits and Features

Fiberglass dune buggy bodies have been around since the 1964s and have become a popular choice for off-road enthusiasts. These lightweight and durable bodies are typically mounted on a Volkswagen Beetle chassis and offer an affordable way to get into the world of off-road driving.

One of the key advantages of fiberglass dune buggy bodies is their versatility. They can be customized to suit the owner’s preferences, with a wide range of colors and styles available. Many manufacturers offer a variety of options, including different hoods, fenders, and other body parts, allowing owners to create a unique look for their vehicle.

Another advantage of fiberglass dune buggy bodies is their durability. Unlike traditional metal bodies, fiberglass is resistant to rust and corrosion, making it ideal for use in off-road environments. It is also lightweight, which helps to improve the vehicle’s performance and fuel efficiency. Overall, fiberglass dune buggy bodies offer a cost-effective and customizable option for off-road enthusiasts looking to build their own vehicle.

History of Fiberglass Dune Buggy Bodies

Fiberglass dune buggy bodies have a rich history that dates back to the 1964s. The first fiberglass dune buggy was the Meyers Manx, designed and built by Bruce Meyers in 1964. Meyers created his fiberglass bodies as a “kit car,” using the Volkswagen Beetle chassis. The Meyers Manx became an instant hit and inspired many other companies worldwide to make similar bodies and kits. These types of dune buggies are known as “clones.”

The popularity of the Meyers Manx led to the emergence of many other dune buggy designs, such as the Sportster and the Burro. The Burro was designed and built by Hilder “Tiny” Thompson and was not stylish at all, but it was selling. About a year later, many Burros were popping up at dunes around Southern California.

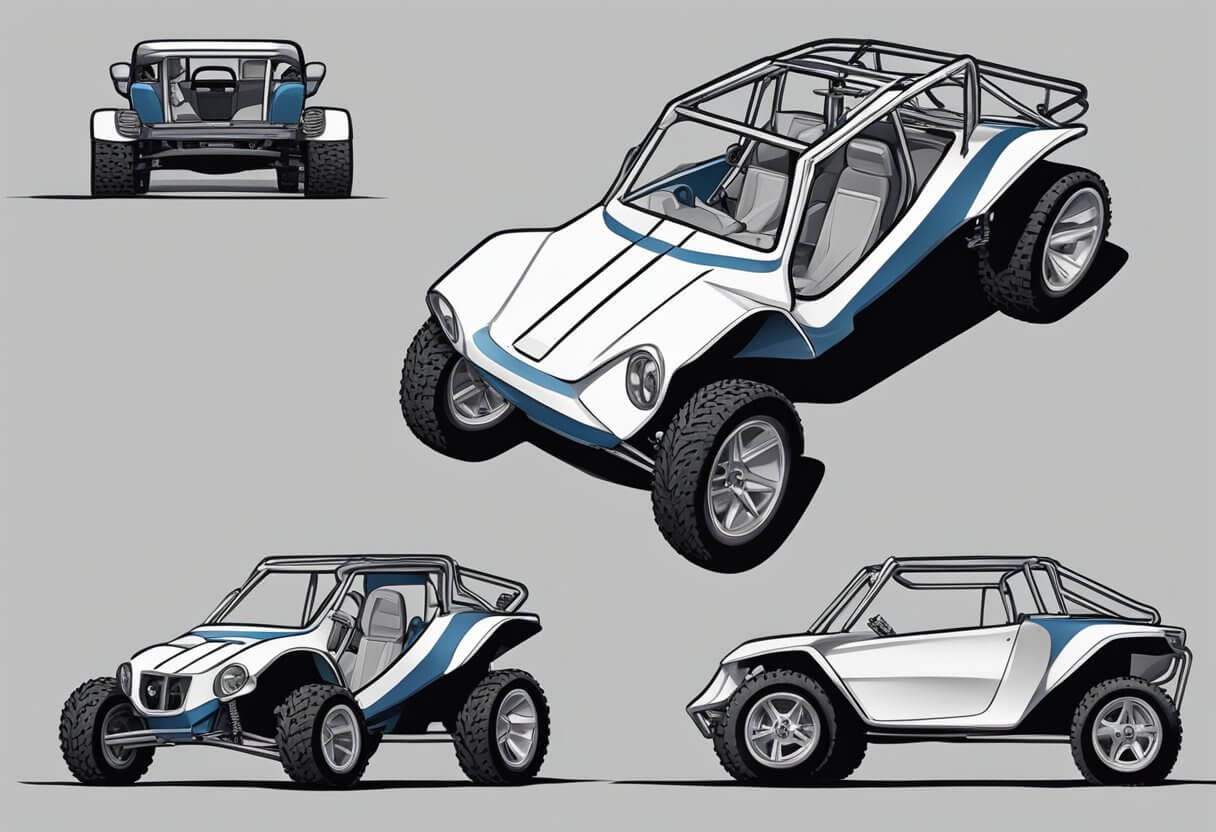

Over the years, fiberglass dune buggy bodies have evolved, and many different types of bodies are now available. Some of the most popular types of fiberglass dune buggy bodies include:

- Classic Manx-style bodies: These are the most popular and recognizable types of dune buggy bodies. They are designed to fit on a shortened Volkswagen Beetle chassis and feature a distinct, rounded design.

- T-Bucket-style bodies: These bodies are designed to fit on a custom chassis and feature a more traditional hot rod-style design.

- Sandrail-style bodies: These bodies are designed for off-road use and feature a more rugged, angular design.

- Street-legal bodies: These bodies are designed to meet the requirements for street use and feature a more practical, functional design.

Today, fiberglass dune buggy bodies are still popular among off-road enthusiasts and kit car builders. They offer a lightweight, customizable alternative to traditional off-road vehicles and are relatively easy to build and maintain.

Materials and Composition

Fiberglass Resin Types

Fiberglass bodies for dune buggies are made using different types of resins. The most common resin used is polyester resin, which is a thermosetting plastic that can be cured to a solid state. Polyester resin is preferred for its low cost and ease of use. It is also resistant to water and chemicals, making it ideal for outdoor use. However, it is not as strong as other resins and can crack or break under stress.

Epoxy resin is another type of resin used in fiberglass bodies. It is stronger and more durable than polyester resin, but it is also more expensive and more difficult to work with. Epoxy resin is preferred for high-performance applications, where strength and durability are crucial.

Reinforcement Materials

To make fiberglass bodies stronger and more durable, reinforcement materials are added to the resin. The most common reinforcement material used is fiberglass mat, which is made up of woven strands of fiberglass. The fiberglass mat is placed in layers in the mold, and the resin is applied to it. The layers of mat and resin are built up until the desired thickness is achieved.

Another reinforcement material used is fiberglass cloth, which is similar to fiberglass mat but is made up of woven strands of fiberglass. Fiberglass cloth is preferred for its strength and durability, but it is also more expensive than fiberglass mat.

Gel Coats and Finishes

Gel coat is a type of resin that is applied to the surface of the fiberglass body to give it a smooth, glossy finish. Gel coat is preferred for its durability and resistance to UV rays and chemicals. It is available in different colors and can be custom-matched to the color of the dune buggy.

After the gel coat is applied, the body is sanded and polished to give it a high-gloss finish. The body can also be painted with automotive paint to give it a custom look.

Design and Manufacturing

Mold Design

The process of designing a fiberglass dune buggy body starts with the creation of a mold. The mold is made by creating a negative of the desired shape of the body. This negative is then used to create a positive mold, which will be used to create the final product. The mold must be designed with precision to ensure that the final product is accurate and consistent.

Fabrication Process

Once the mold is complete, the fabrication process can begin. The process starts with the application of a gel coat to the mold. The gel coat is a special resin that provides a smooth, glossy finish to the final product. Once the gel coat has been applied, layers of fiberglass are added to the mold. The number of layers used will depend on the desired thickness of the final product. The fiberglass is then allowed to cure, which can take several hours.

Once the fiberglass has cured, the body is removed from the mold. Any excess fiberglass is trimmed away, and the body is sanded and polished to achieve a smooth finish. The body can then be painted or left unpainted, depending on the customer’s preference.

Quality Control

Quality control is an important part of the manufacturing process for fiberglass dune buggy bodies. Each body must be inspected to ensure that it meets the desired specifications. This includes checking for any defects in the gel coat or fiberglass, as well as ensuring that the body is the correct size and shape. Any defects that are found must be corrected before the body is sold to a customer.

Types of Fiberglass Dune Buggy Bodies

Fiberglass dune buggy bodies come in various types and designs. Here are the two main categories of fiberglass dune buggy bodies:

Standard Bodies

Standard bodies are the most common type of fiberglass dune buggy bodies. They are designed to fit on a standard VW Beetle chassis and come in a range of sizes and shapes. The standard bodies are made to be lightweight, aerodynamic, and durable. They are also easy to install and maintain.

Custom Designs

Custom designs are made to order and are tailored to the specific needs and preferences of the customer. They can come in any shape, size, and color, and can be designed to fit on any type of chassis. Custom designs are ideal for those who want a unique and personalized dune buggy. However, they can be more expensive than standard bodies due to the customization process.

According to the search results, some popular types of fiberglass dune buggy bodies include the Meyers Manx Monocoque, the Bremen Motorsports Ciatation, and the Bandit Dune Buggies full-length body kit. Each of these bodies has its unique features and benefits, and they all come in standard and custom designs.

When choosing a fiberglass dune buggy body, it is important to consider factors such as the intended use, budget, and personal preferences. Standard bodies are ideal for those who want a reliable and affordable option, while custom designs are perfect for those who want a one-of-a-kind dune buggy.

Installation and Fitting

When it comes to installing and fitting a fiberglass dune buggy body, there are a few important factors to consider. This section will cover the two major aspects of installation and fitting: mounting to the chassis and alignment and adjustment.

Mounting to Chassis

The first step in installing a fiberglass dune buggy body is to mount it to the chassis. This process can vary depending on the specific body and chassis being used, but generally involves the use of metal bolts to attach the underside of the body to the chassis.

It is important to ensure that the body is mounted securely and properly aligned with the chassis to prevent any dangerous or unstable driving conditions. Some bodies may require additional brackets or modifications to ensure a proper fit.

Alignment and Adjustment

Once the body is mounted to the chassis, it is important to check the alignment and make any necessary adjustments. This includes ensuring that the body is level and straight, and that the doors and other components fit properly.

Some fiberglass bodies may require additional adjustments or modifications to ensure a proper fit. It is important to carefully follow the manufacturer’s instructions and use any recommended tools or equipment to make these adjustments.

Maintenance and Care

Cleaning and Polishing

Maintaining the appearance of a fiberglass dune buggy body is essential to keep it looking new and attractive. Regular cleaning and polishing will help to remove dirt, grime, and other contaminants that can accumulate on the surface of the body. A clean and polished body will not only look better but will also be more resistant to damage caused by exposure to the elements.

To clean a fiberglass dune buggy body, it is recommended to use a mild soap and water solution. Harsh chemicals or abrasive cleaners should be avoided as they can damage the surface of the body. After cleaning, the body should be dried thoroughly using a soft cloth or chamois.

Polishing the body can help to restore its shine and protect it from UV rays. A high-quality fiberglass polish should be used for this purpose. The polish should be applied using a soft cloth or applicator pad and buffed to a shine using a clean, dry cloth.

Repair and Restoration

Fiberglass dune buggy bodies are durable and long-lasting, but they can still be damaged over time. Cracks, chips, and other types of damage can occur due to accidents, exposure to the elements, or normal wear and tear. Fortunately, most types of damage can be repaired using simple tools and materials.

For minor damage, such as small cracks or chips, a fiberglass repair kit can be used. These kits typically include a resin and hardener that can be mixed together and applied to the damaged area. After the resin has cured, the repaired area can be sanded and polished to match the surrounding area.

For more extensive damage, such as large cracks or holes, it may be necessary to replace the damaged section of the body. Replacement body panels can be purchased from a variety of suppliers and can be installed using basic hand tools.

Regular maintenance and care can help to extend the life of a fiberglass dune buggy body and keep it looking great for years to come. By following a few simple steps, owners can keep their bodies in top condition and enjoy their dune buggies to the fullest.

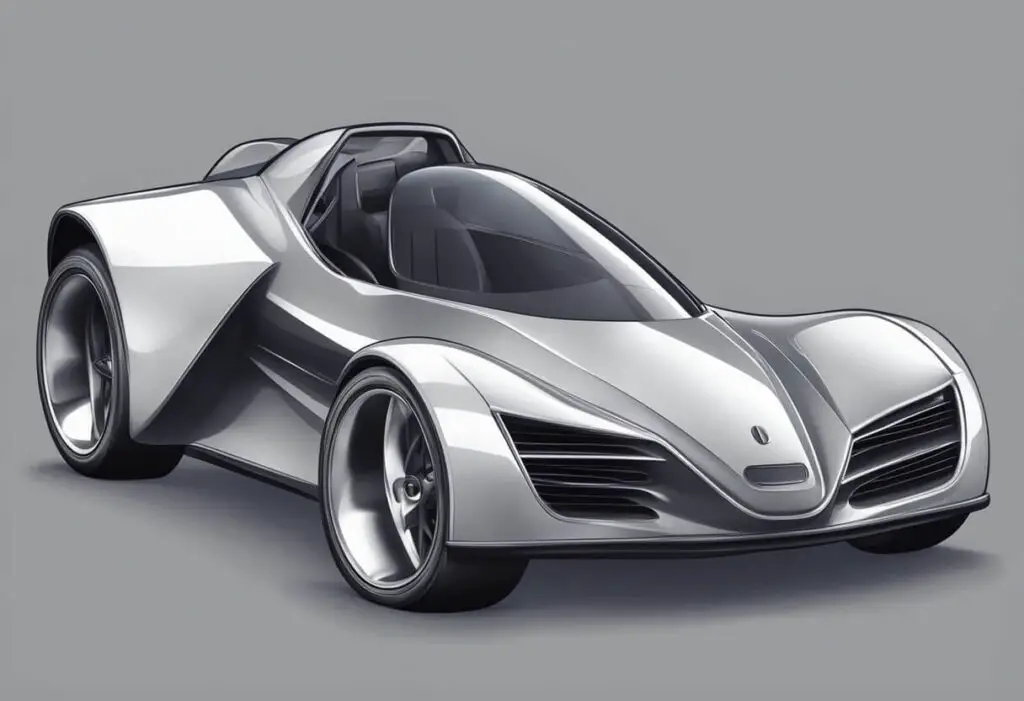

Performance and Aerodynamics

Fiberglass dune buggy bodies are designed to enhance the off-road performance of the vehicle. The lightweight nature of fiberglass makes it an ideal material for dune buggies. Fiberglass dune buggy bodies are lighter than their counterparts made of metal, which reduces the overall weight of the vehicle. This reduction in weight increases the acceleration and speed of the dune buggy, making it a more agile and responsive vehicle.

The aerodynamic design of fiberglass dune buggy bodies is another factor that improves the performance of the vehicle. The sleek and streamlined design of the body reduces the air resistance, which in turn increases the speed of the vehicle. The reduction in air resistance also improves the fuel efficiency of the vehicle, making it more economical to run.

The use of fiberglass dune buggy bodies also offers the advantage of customization. Fiberglass is a highly versatile material that can be molded into any shape or form. This allows for the creation of unique and customized dune buggy bodies that can be tailored to the specific needs and preferences of the driver.

Customization and Accessories

Paint and Graphics

One of the biggest advantages of fiberglass dune buggy bodies is the ability to customize the paint and graphics to your liking. With a fiberglass body, you can achieve a smooth and seamless finish that is difficult to achieve with metal bodies. Additionally, fiberglass is easy to paint and can be painted in any color or design you desire.

To ensure a high-quality paint job, it is important to properly prepare the surface of the fiberglass body. This includes sanding and cleaning the surface to remove any dirt, oil, or debris. A primer should then be applied to the surface to help the paint adhere properly.

When it comes to graphics, the possibilities are endless. From stripes and flames to custom designs and logos, fiberglass dune buggy bodies offer a blank canvas for your creativity. Vinyl decals are a popular option for adding graphics to a fiberglass body, as they are easy to apply and can be removed without damaging the paint.

Body Modifications

Another advantage of fiberglass dune buggy bodies is the ease of making body modifications. Fiberglass can be easily cut and shaped to create custom body modifications such as scoops, vents, and spoilers. These modifications not only add to the aesthetic appeal of the dune buggy but can also improve its performance.

Some popular body modifications for dune buggies include adding a roll cage for safety, installing a sunroof for an open-air driving experience, and adding fender flares for a more aggressive look. Additionally, fiberglass dune buggy bodies can be easily modified to accommodate different engine sizes or suspension setups.

Overall, fiberglass dune buggy bodies offer a wide range of customization options and accessories to make your dune buggy truly unique. With the ability to easily paint and modify the body, the possibilities are endless for creating a one-of-a-kind dune buggy that reflects your personal style and preferences.