Dune Buggy Engine: Guide to Choosing the Right Type

With the growing popularity of thrill-seeking outdoor adventures, custom dune buggies have become a beloved way to tackle sand dunes and rough terrain. But what exactly goes into choosing the right engine to power your rugged ride?

What type of engine should you use in a dune buggy for optimal power and performance?

The most common and suitable engine types for dune buggies are air-cooled gasoline engines, which offer a good balance of power, performance, weight and cost. However, factors like engine size, cooling system, intended use, and budget should be considered when selecting one.

In this article, we’ll cover specifics like:

- Key specifications to evaluate like horsepower, torque, and cooling system

- Pros and cons of other engine types like diesel and electric

- Important components in the engine like pistons, crankshaft, and valvetrain

- Fuel system considerations including carburetors vs fuel injection

- The role of the exhaust system in engine performance

- Maintenance and upgrades to improve power

By understanding all these factors, you’ll be equipped to customize an engine tailored to your off-road adventuring needs!

Dune Buggy Engine Basics

Engine Types

When it comes to choosing an engine for a dune buggy, there are several options available. The most common engine types used in dune buggies are gasoline, diesel, and electric. Gasoline engines are the most popular choice because they offer good power and performance. Diesel engines are more fuel-efficient, but they are also heavier and more expensive. Electric engines are the most environmentally friendly, but they have limited range and require frequent recharging.

Power and Performance

The power and performance of a dune buggy engine depend on several factors, including the engine type, size, and configuration. Gasoline engines are typically more powerful than diesel or electric engines of the same size. A 600 cc gasoline engine, for example, should provide plenty of power for most off-road buggies. However, it’s important to keep in mind that more power often means more weight, which can affect the buggy’s handling and performance.

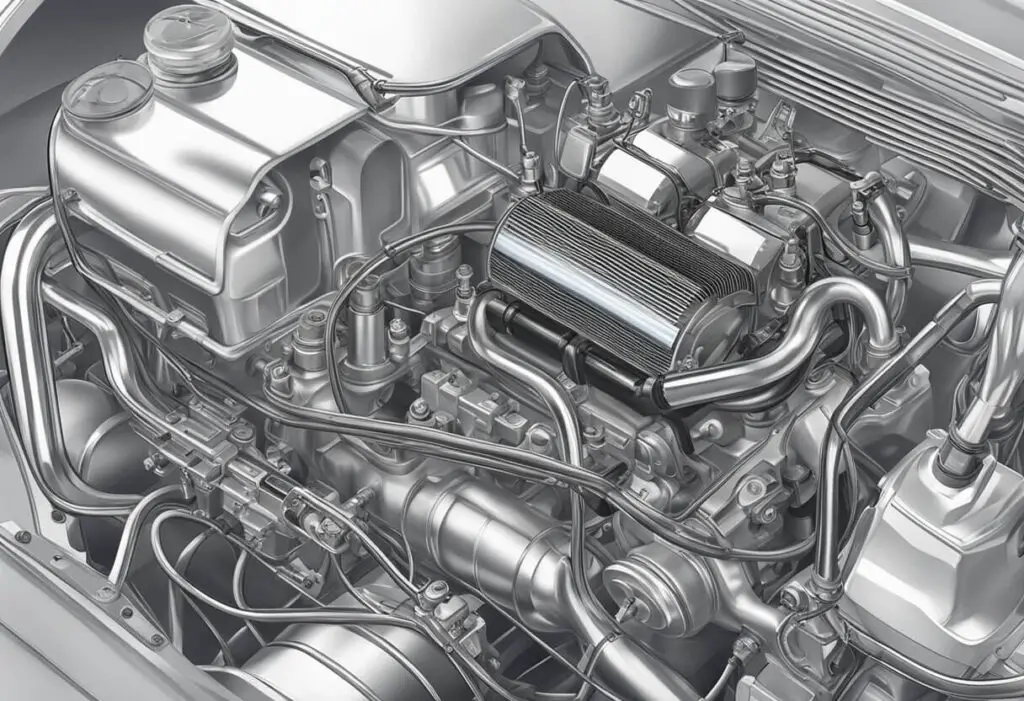

Cooling Systems

Dune buggy engines generate a lot of heat, so it’s important to have an effective cooling system in place. Air-cooled engines are the most common type used in dune buggies because they are simple and reliable. However, liquid-cooled engines are becoming more popular because they offer better cooling performance and can be more efficient. Liquid-cooled engines also allow for more precise temperature control, which can help improve engine performance and longevity.

Overall, choosing the right engine for a dune buggy depends on several factors, including power, performance, weight, and cost. It’s important to consider all of these factors before making a decision to ensure that the engine meets your specific needs and requirements.

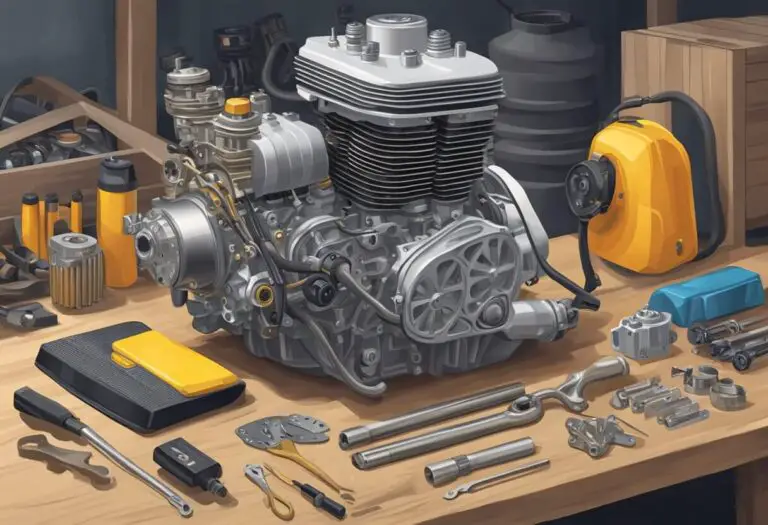

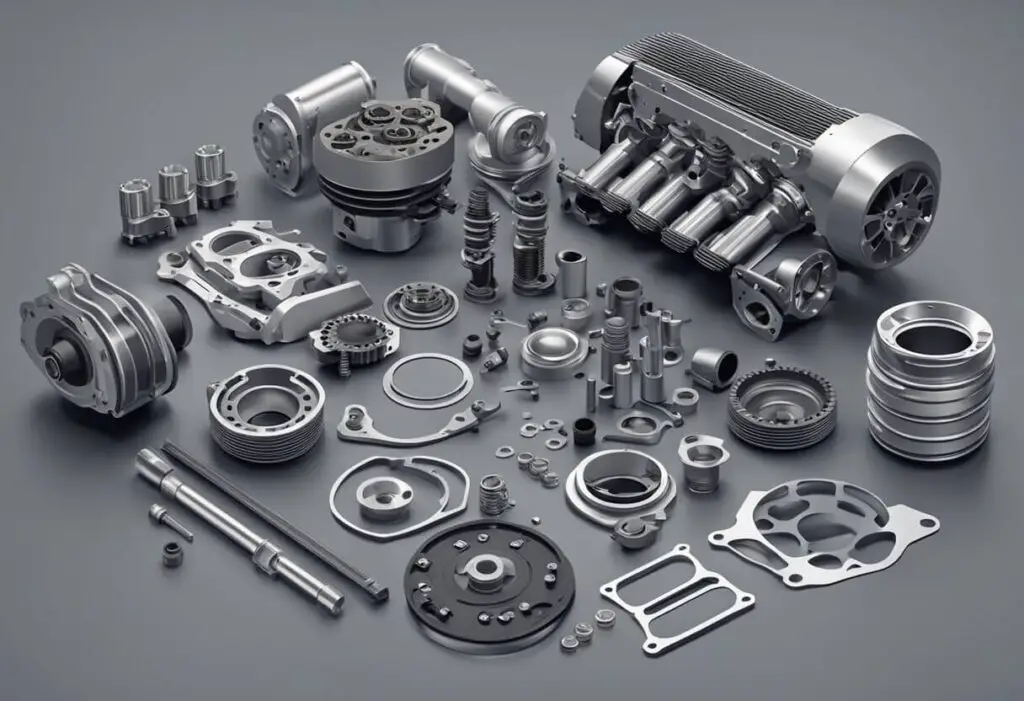

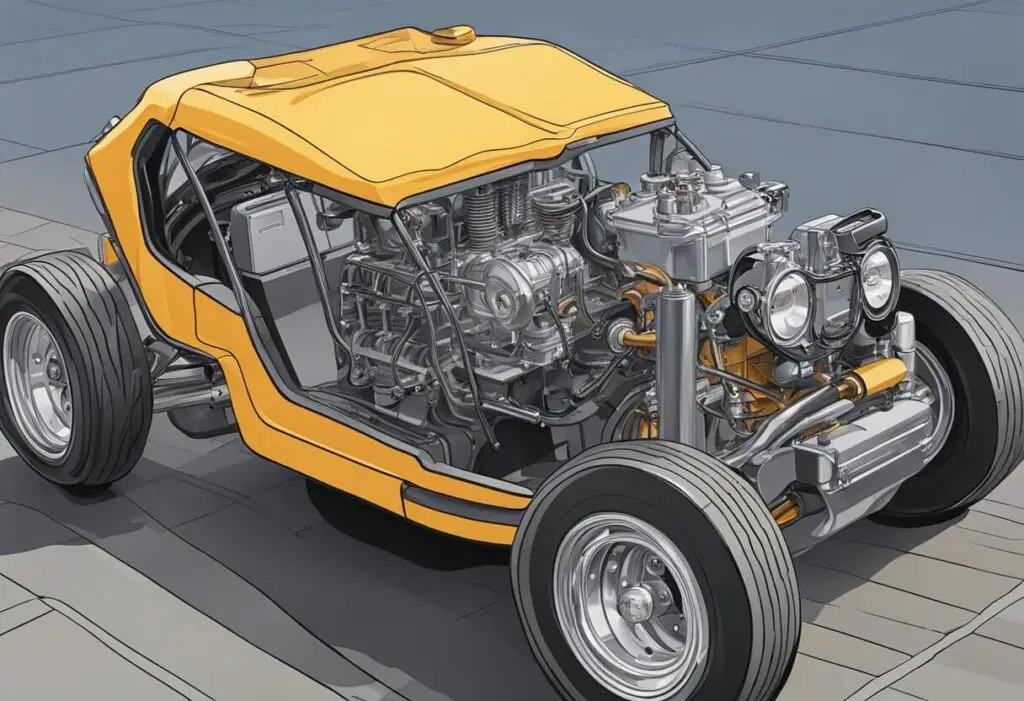

Engine Components

When it comes to building or maintaining a dune buggy engine, it’s crucial to understand the various components that make up the engine. These components work together to ensure that the engine runs smoothly and efficiently. In this section, we’ll take a closer look at some of the key engine components, including the cylinder block, pistons and rings, crankshaft and connecting rods, and valvetrain.

Cylinder Block

The cylinder block is the foundation of the engine, and it houses the cylinders, pistons, and other engine components. When selecting a cylinder block, it’s important to consider factors such as the material, bore size, and cylinder wall thickness. Common materials used for cylinder blocks include aluminum and cast iron, with each material offering its own set of advantages and disadvantages.

Pistons and Rings

Pistons and rings are critical engine components that work together to ensure that the engine runs smoothly. Pistons are responsible for transferring the energy from the combustion process to the crankshaft, while rings help to seal the combustion chamber and prevent oil from entering the combustion chamber. When selecting pistons and rings, it’s important to consider factors such as the material, size, and compression ratio.

Crankshaft and Connecting Rods

The crankshaft and connecting rods are responsible for converting the up-and-down motion of the pistons into rotational motion that can be used to power the vehicle. When selecting a crankshaft and connecting rods, it’s important to consider factors such as the material, weight, and balance. A well-balanced crankshaft and connecting rods can help to reduce vibration and improve engine performance.

Valvetrain

The valvetrain is responsible for opening and closing the engine’s valves, which allows air and fuel to enter the combustion chamber and exhaust gases to exit the engine. When selecting valvetrain components, it’s important to consider factors such as the valve size, valve lift, and camshaft profile. A well-designed valvetrain can help to improve engine performance and efficiency.

Fuel System

The fuel system is a crucial component of a dune buggy engine, providing the necessary fuel to power the vehicle. There are several options for fuel systems, including carburetors and fuel injection, as well as various types of fuel pumps and filters.

Carburetors

Carburetors are a common choice for dune buggy engines, as they are relatively simple and easy to maintain. They work by mixing fuel and air in the carburetor’s throat, creating a combustible mixture that is then delivered to the engine. Carburetors come in a variety of sizes and types, and choosing the right one for your dune buggy engine will depend on several factors, including the engine size and intended use of the vehicle.

Fuel Injection

Fuel injection is another option for dune buggy engines, providing more precise control over the fuel delivery system. This method uses electronic sensors to monitor the engine’s performance and adjust the fuel delivery accordingly. Fuel injection can improve fuel efficiency, power, and emissions, but it is more complex and expensive than carburetors.

Fuel Pumps and Filters

Regardless of the fuel system chosen, a dune buggy engine will require a fuel pump and filter to deliver fuel to the engine. Fuel pumps come in several varieties, including mechanical and electric, and must be matched to the engine’s fuel requirements. Fuel filters are also important, preventing dirt and debris from entering the engine and causing damage. It is important to choose high-quality fuel pumps and filters to ensure optimal performance and reliability.

Exhaust System

The exhaust system of a dune buggy is a crucial component that plays a critical role in ensuring a smooth and efficient operation of the engine. It is responsible for removing the exhaust gases from the engine and directing them out of the vehicle. In this section, we will discuss the various components of the exhaust system, including headers, mufflers, and exhaust pipes.

Headers

Headers are an essential part of the exhaust system that connects the engine to the exhaust pipes. They are designed to improve the flow of exhaust gases from the engine, which results in improved engine performance. Headers come in different sizes and shapes, and they are made from various materials such as stainless steel, aluminum, and ceramic-coated steel.

Mufflers

Mufflers are another crucial component of the exhaust system that is responsible for reducing the noise produced by the engine. They are designed to absorb the sound waves produced by the engine and convert them into heat energy. Mufflers come in different sizes and shapes, and they are made from various materials such as stainless steel, aluminum, and fiberglass.

Exhaust Pipes

Exhaust pipes are the final part of the exhaust system that directs the exhaust gases out of the vehicle. They are designed to be durable and resistant to high temperatures and corrosion. Exhaust pipes come in different sizes and shapes, and they are made from various materials such as stainless steel, aluminum, and mild steel.

Electrical System

Ignition System

The ignition system of a dune buggy is responsible for starting the engine. In an electric dune buggy, the ignition system is replaced by a motor controller that controls the electric motor. The motor controller receives input from the accelerator pedal and sends power to the motor to make the dune buggy move. The motor controller also regulates the speed and torque of the electric motor.

Battery and Alternator

The battery in an electric dune buggy provides power to the motor controller and other electrical components. The battery is charged by plugging the dune buggy into an electrical outlet. The alternator is not needed in an electric dune buggy as it is in a gas-powered dune buggy.

The battery in an electric dune buggy is a lithium-ion battery pack. Lithium-ion batteries are lightweight and have a high energy density, making them ideal for electric vehicles. The battery pack is usually located under the seats or in the floor of the dune buggy.

Wiring and Connectors

The wiring and connectors in an electric dune buggy are critical components that ensure that power is delivered to the motor controller and other electrical components. The wiring and connectors must be properly insulated and protected from moisture and dirt.

The wiring and connectors in an electric dune buggy are usually color-coded to make it easier to identify them. The wiring and connectors are also labeled to indicate their function. It is essential to follow the wiring diagram provided by the manufacturer when installing or repairing the wiring and connectors.

Engine Maintenance

Maintaining the engine of a dune buggy is crucial to ensure its longevity and reliability. Regular maintenance can prevent costly repairs and keep the buggy running smoothly. Here are some important maintenance tasks that should be performed on a regular basis.

Oil Changes

Regular oil changes are essential to keep the engine running smoothly. The oil lubricates the engine, reducing friction and preventing wear and tear. Over time, the oil can become contaminated with dirt and debris, reducing its effectiveness. It is recommended to change the oil every 3,000 miles or every three months, whichever comes first.

Coolant Flush

The coolant in the engine helps regulate the temperature and prevent overheating. Over time, the coolant can become contaminated with rust and debris, reducing its effectiveness. It is recommended to flush the coolant system every two years or 30,000 miles, whichever comes first.

Belt Inspections

The belts in the engine, such as the serpentine belt, help power various components such as the alternator and water pump. Over time, the belts can become worn and cracked, reducing their effectiveness. It is recommended to inspect the belts every 60,000 miles and replace them if necessary.

By performing these regular maintenance tasks, dune buggy owners can ensure their engines stay in top condition and avoid costly repairs.

Troubleshooting Common Issues

Dune buggies can experience various issues that can affect their performance. Here are some common problems and their possible solutions:

Overheating

Overheating is a common problem in dune buggies, especially during hot summer months. It can be caused by a variety of factors, such as a malfunctioning cooling system, low coolant levels, or a dirty radiator. To troubleshoot this issue, follow the steps below:

- Check the coolant level and add more if necessary.

- Inspect the radiator for any signs of damage or corrosion.

- Clean the radiator and remove any debris or dirt that may be blocking the airflow.

- Check the water pump for any signs of leaks or damage.

- Inspect the thermostat and replace it if necessary.

Oil Leaks

Oil leaks can be a major problem in dune buggies, as they can cause the engine to seize up or fail completely. They can be caused by a variety of factors, such as worn-out gaskets, damaged seals, or loose fittings. To troubleshoot this issue, follow the steps below:

- Inspect the engine for any signs of oil leaks, such as puddles or stains.

- Check the gaskets and seals for any signs of wear or damage.

- Tighten any loose fittings or connections.

- Replace any damaged gaskets or seals.

Misfires

Misfires can cause the engine to run poorly or even stall completely. They can be caused by a variety of factors, such as a faulty ignition system, clogged fuel injectors, or a dirty air filter. To troubleshoot this issue, follow the steps below:

- Check the spark plugs for any signs of wear or damage.

- Inspect the ignition system for any loose connections or damaged components.

- Clean or replace the air filter.

- Check the fuel injectors for any signs of clogs or damage.

- Replace any damaged or worn-out components in the ignition or fuel system.

By following these troubleshooting steps, dune buggy owners can identify and resolve common issues that can affect their vehicle’s performance.

Performance Upgrades

Dune buggy engines are known for their reliability and endurance, but they can always benefit from a little boost in performance. There are several ways to upgrade a dune buggy engine, including turbocharging, nitrous oxide systems, and engine tuning.

Turbocharging

Turbocharging is a popular way to increase the power of a dune buggy engine. It works by compressing the air that enters the engine, allowing more air to enter the combustion chamber and resulting in a more powerful explosion. This can lead to significant gains in horsepower and torque.

However, it’s important to note that turbocharging can also put additional stress on an engine, so it’s crucial to ensure that the engine is built to handle the increased power. Additionally, turbocharging can be expensive and time-consuming, so it may not be the best option for everyone.

Nitrous Oxide Systems

Nitrous oxide systems, also known as NOS, are another way to increase the power of a dune buggy engine. NOS works by injecting nitrous oxide into the engine, which increases the amount of oxygen available for combustion. This results in a more powerful explosion and can lead to significant gains in horsepower and torque.

However, like turbocharging, NOS can also put additional stress on an engine, so it’s important to ensure that the engine is built to handle the increased power. Additionally, NOS can be dangerous if not used properly, so it’s crucial to follow all safety guidelines when using it.

Engine Tuning

Engine tuning is a less expensive and less risky way to increase the power of a dune buggy engine. It involves making adjustments to the engine’s fuel and air delivery systems to optimize its performance. This can lead to modest gains in horsepower and torque, but it can also improve the engine’s overall efficiency and drivability.

Engine tuning can be done by a professional mechanic or by the owner of the dune buggy with the right tools and knowledge. It’s important to note that engine tuning can also have negative effects on the engine if done improperly, so it’s crucial to follow all recommended guidelines and best practices.

Legal and Environmental Considerations

When it comes to owning a dune buggy, there are legal and environmental considerations to keep in mind. It is important to ensure that your dune buggy is compliant with local regulations to avoid any legal issues.

Emission Standards

Emission standards are regulations that limit the amount of pollutants that a vehicle can emit. These standards vary by state and country, and it is important to ensure that your dune buggy meets the requirements in your area.

One way to ensure compliance with emission standards is to install a catalytic converter. A catalytic converter is a device that reduces the amount of pollutants in the exhaust gases. It is important to note that not all dune buggy engines are compatible with catalytic converters, so it is important to check with your mechanic before installing one.

Noise Regulations

Dune buggies can be loud, and there are regulations in place to limit the amount of noise that a vehicle can produce. These regulations vary by state and country, and it is important to ensure that your dune buggy meets the requirements in your area.

One way to reduce the noise produced by your dune buggy is to install a muffler. A muffler is a device that reduces the noise produced by the engine. It is important to note that not all dune buggy engines are compatible with mufflers, so it is important to check with your mechanic before installing one.

In conclusion, it is important to ensure that your dune buggy is compliant with local regulations to avoid any legal issues. By installing a catalytic converter and a muffler, you can reduce the emissions and noise produced by your dune buggy, making it more environmentally friendly and compliant with local regulations.