Dune Buggy Wiring Harness: A Comprehensive Guide

Dune buggies are fun and exciting vehicles to drive, but they require a lot of maintenance and attention to detail. One of the most important aspects of a dune buggy is its wiring harness, which is responsible for distributing power throughout the vehicle. Without a properly functioning wiring harness, a dune buggy can experience a host of problems, from electrical shorts to complete system failure.

A dune buggy wiring harness is a complex system that connects all of the vehicle’s electrical components, including the battery, alternator, starter, and lights. It is responsible for routing power to the various systems and ensuring that everything works together seamlessly. A good wiring harness is essential to the safe and reliable operation of a dune buggy, and it is important to choose one that is designed specifically for the make and model of your vehicle.

There are many different types of dune buggy wiring harnesses available on the market, each with its own unique features and advantages. Some are designed for specific makes and models of dune buggies, while others are more universal and can be used with a variety of different vehicles. When choosing a wiring harness, it is important to consider factors such as the quality of the materials, the ease of installation, and the level of customization that is available.

Understanding Dune Buggy Wiring Harnesses

When it comes to dune buggies, having a reliable wiring harness is absolutely crucial. A wiring harness is a collection of wires that connect all of the electrical components in your vehicle. It serves as the central nervous system of your dune buggy, allowing it to function properly. In this section, we will discuss the basics of electrical systems, components of a wiring harness, and types of wiring harnesses.

Basics of Electrical Systems

Electrical systems in dune buggies are composed of a battery, alternator, starter, and various electrical components such as lights, gauges, and accessories. The battery provides power to the electrical components, while the alternator charges the battery and supplies power to the electrical system when the engine is running. The starter is used to start the engine.

Components of a Wiring Harness

A wiring harness for a dune buggy includes wires, connectors, terminals, and fuses. The wires are used to connect the different electrical components in the vehicle. Connectors are used to join wires together, while terminals are used to connect wires to electrical components. Fuses protect the electrical system from damage caused by electrical overload.

Types of Wiring Harnesses

There are two main types of wiring harnesses for dune buggies: universal and custom. Universal wiring harnesses are designed to fit a variety of different dune buggies and are generally less expensive than custom wiring harnesses. Custom wiring harnesses are designed specifically for a particular make and model of dune buggy and are generally more expensive than universal wiring harnesses.

Designing a Dune Buggy Wiring Harness

When designing a wiring harness for a dune buggy, there are several factors to consider to ensure that the electrical system is safe, reliable, and effective. This section will cover some of the key considerations when designing a dune buggy wiring harness.

Wiring Diagrams and Schematics

Before starting the design process, it is important to have a clear understanding of the wiring diagram and schematics for the dune buggy. This will help to identify the various components of the electrical system, their connections, and the wiring required to connect them. A clear and accurate wiring diagram will also help to troubleshoot any issues that may arise in the future.

Choosing the Right Wire Gauge

Selecting the right wire gauge is crucial for the safe and effective operation of the dune buggy’s electrical system. The wire gauge should be chosen based on the maximum current that will flow through it, as well as the length of the wire. A wire that is too thin may overheat and cause a fire, while a wire that is too thick may be difficult to work with and add unnecessary weight to the vehicle.

Circuit Protection and Safety

Circuit protection is an important consideration when designing a dune buggy wiring harness. Fuses and circuit breakers should be included in the design to protect the electrical system from overloading and short circuits. It is also important to ensure that all electrical connections are secure and properly insulated to prevent electrical shock and other hazards.

In summary, designing a dune buggy wiring harness requires careful consideration of wiring diagrams and schematics, wire gauge selection, and circuit protection and safety. By taking these factors into account, a safe and reliable electrical system can be designed for the dune buggy.

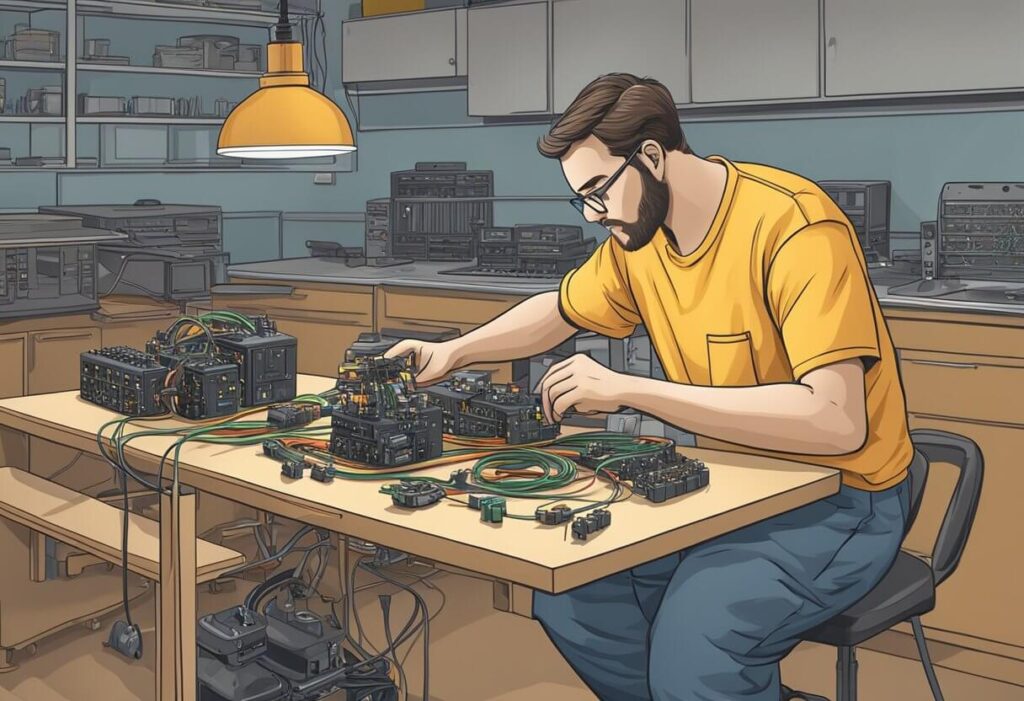

Installation of a Wiring Harness

Tools and Materials Needed

Before starting the installation process, it is important to gather all the necessary tools and materials. Here is a list of items that are required to install a dune buggy wiring harness:

- Wire cutters/strippers

- Crimping tool

- Electrical tape

- Screwdriver

- Heat shrink tubing

- Soldering iron and solder

- Wiring harness kit

- Owner’s manual

Step-by-Step Installation Guide

Once all the required tools and materials are gathered, the installation process can begin. Here is a step-by-step guide to installing a dune buggy wiring harness:

- Disconnect the battery: Before starting the installation process, disconnect the battery to avoid any electrical hazards.

- Remove the old wiring harness: Remove the old wiring harness from the vehicle and make sure to label all the wires. This will make the installation process easier.

- Install the new wiring harness: Install the new wiring harness by following the instructions provided in the owner’s manual. Make sure to match the labels on the wires to their corresponding connections.

- Connect the wires: Once the new wiring harness is installed, connect the wires to their corresponding connections using the crimping tool and electrical tape.

- Solder the wires: For added security, solder the wires and cover them with heat shrink tubing.

- Test the connections: After connecting and soldering the wires, test the connections to ensure that everything is working properly.

Troubleshooting Common Issues

Sometimes, issues may arise during the installation process. Here are some common issues and their solutions:

- Loose connections: If the connections are loose, use the crimping tool to tighten them.

- Faulty wiring: If the wiring is faulty, replace it with a new one.

- Blown fuses: If the fuses are blown, replace them with new ones of the same amperage.

By following this step-by-step guide and troubleshooting common issues, the installation of a dune buggy wiring harness can be done easily and safely.

Maintenance and Upgrades

Regular Maintenance Tips

Maintaining a dune buggy’s wiring harness is essential for ensuring that its electrical system functions properly and safely. Here are some regular maintenance tips to keep in mind:

- Regularly check the wiring harness for signs of wear and tear, such as frayed wires or loose connectors.

- Clean the wiring harness periodically to remove any dirt or debris that may have accumulated on it.

- Make sure that all electrical connections are tight and secure.

- Check the battery and alternator regularly to ensure that they are functioning properly.

Upgrading Your Wiring Harness

If you’re looking to upgrade your dune buggy’s wiring harness, there are a few things to consider. First, make sure that the new harness is compatible with your buggy’s make and model. Second, look for a harness that is made from high-quality materials and is designed to withstand the rigors of off-road use. Finally, make sure that the new harness comes with a detailed installation guide to make the process as easy as possible.

Handling Electrical Failures

Even with regular maintenance and upgrades, electrical failures can still occur. Here are some tips for handling electrical failures in your dune buggy:

- Check the fuses and relays to make sure that they are functioning properly.

- Use a multimeter to test the electrical connections and identify any faults.

- If you’re unable to diagnose the problem on your own, seek the help of a professional mechanic or electrician.

By following these regular maintenance tips, upgrading your wiring harness when necessary, and knowing how to handle electrical failures, you can ensure that your dune buggy’s electrical system functions properly and safely.

Regulatory Compliance and Safety

Industry Standards

Dune buggy wiring harnesses must meet certain industry standards to ensure their safety and reliability. These standards include proper insulation and protection for the wires, as well as the use of high-quality materials that can withstand the rigors of off-road driving. The wiring harness should also be designed to fit the unique electrical needs of a dune buggy.

Legal Requirements

In addition to industry standards, dune buggy wiring harnesses must also comply with legal requirements. These requirements may vary depending on the location of the dune buggy and the intended use of the vehicle. For example, in the United States, the National Highway Traffic Safety Administration (NHTSA) sets safety standards for vehicles, including dune buggies. It is important to ensure that the wiring harness meets these standards to avoid any legal issues.

Safety Certifications

To ensure the safety and reliability of the wiring harness, it is important to look for safety certifications. These certifications indicate that the wiring harness has been tested and meets certain safety standards. Some common safety certifications include the UL (Underwriters Laboratories) mark, which indicates that the wiring harness has been tested for safety and reliability, and the CSA (Canadian Standards Association) mark, which indicates that the wiring harness meets Canadian safety standards.

Overall, it is important to choose a dune buggy wiring harness that meets industry standards, legal requirements, and safety certifications to ensure the safety and reliability of the vehicle.