Electric Motor for Dune Buggy: A Comprehensive Guide

Electric motors have become increasingly popular in the automotive industry. Dune buggies, in particular, have been the focus of many electric motor conversion projects. An electric motor for a dune buggy offers a number of benefits, including improved performance, reduced environmental impact, and reduced maintenance costs.

One of the basics of electric motors for dune buggies is that they are much simpler than their gasoline counterparts. They have fewer moving parts, which means that they require less maintenance and are less prone to breakdowns. They also offer instant torque, which means that they can accelerate quickly and smoothly.

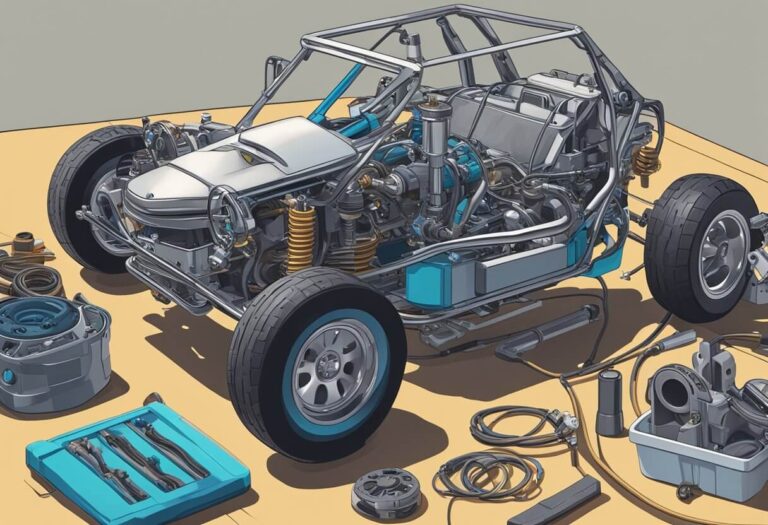

Dune buggy conversion to electric is a process that involves replacing the gasoline engine with an electric motor and battery system. This can be a complex process, but it is becoming more common as the technology improves. Performance considerations, battery and energy storage, electrical systems and components, cooling and thermal management, and maintenance and troubleshooting are all important factors to consider when converting a dune buggy to electric.

Key Takeaways

- Electric motors offer improved performance and reduced maintenance costs for dune buggies.

- Dune buggy conversion to electric is a complex process that requires careful consideration of performance, battery storage, and electrical systems.

- Cooling and thermal management are important factors to consider when converting a dune buggy to electric.

Basics of Electric Motors for Dune Buggies

Electric Motor Types

There are two main types of electric motors used in dune buggies: AC motors and DC motors. AC motors are more efficient and powerful than DC motors, but they are also more expensive. DC motors are less expensive and simpler to control, but they are less efficient and powerful than AC motors.

Power and Torque Characteristics

The power and torque characteristics of an electric motor are important factors to consider when choosing a motor for a dune buggy. Power is measured in kilowatts (kW) and torque is measured in Newton-meters (Nm). A higher power rating means the motor can produce more energy, while a higher torque rating means the motor can provide more force.

Motor Voltage and Power Sources

The voltage of an electric motor determines the power source required to operate it. Low voltage motors operate on batteries, while high voltage motors require a power inverter to convert the battery voltage to the motor’s required voltage.

When selecting a power source for an electric motor, it is important to consider the range and charging time of the battery. Lithium-ion batteries are commonly used in dune buggies due to their high energy density and long lifespan. DC fast charging is also an important feature to consider, as it allows for quick charging times and extended driving range.

Dune Buggy Conversion to Electric

Converting a dune buggy to electric can be a great way to reduce emissions and noise pollution while still enjoying the thrill of off-road driving. There are a few different options available for those looking to make the switch, including conversion kits and DIY conversion steps.

Conversion Kits

One option for converting a dune buggy to electric is to use a conversion kit. These kits typically include all of the necessary components, such as an electric motor, batteries, and a controller. Some popular options include the Flux Buggy conversion kit and the Meyers Manx 2.0 Electric.

It’s important to note that conversion kits can be expensive, and may require some technical expertise to install properly. Additionally, not all conversion kits are compatible with all types of dune buggies, so it’s important to do your research before making a purchase.

DIY Conversion Steps

For those who are mechanically inclined, it is possible to convert a dune buggy to electric using a combination of off-the-shelf components and custom fabrication. This approach can be more affordable than using a conversion kit, but it also requires more time and effort.

Some of the key steps involved in a DIY dune buggy conversion include:

- Removing the existing engine and transmission

- Installing an electric motor and controller

- Adding batteries and a battery management system

- Fabricating custom mounts and brackets

- Wiring the system and testing for proper function

DIY conversions can be tough. Things may not work right away. But with patience, you can make a special, eco-friendly off-road vehicle.

Performance Considerations

Speed and Acceleration

When considering the performance of an electric motor for a dune buggy, speed and acceleration are two key factors to keep in mind. Electric motors can provide instant torque, allowing for quick acceleration and impressive top speeds. However, the maximum speed and acceleration of an electric dune buggy will depend on several factors, including the power of the motor, the weight of the vehicle, and the type of terrain it will be driven on.

According to a search result, the Meyers Manx 2.0 Electric dune buggy can do 0-60 mph in 4.5 seconds with a 202hp motor. This is an impressive acceleration rate for an electric vehicle, and it’s important to note that this is just one example. Other electric dune buggies may have different acceleration rates depending on their specific motor and design.

Handling and Stability

Another important consideration when it comes to electric dune buggy performance is handling and stability. Electric motors tend to have a lower center of gravity than gas engines, which can improve handling and stability on rough terrain. Additionally, electric motors don’t produce as much heat as gas engines, which can help prevent overheating and improve overall performance.

However, it’s important to note that the handling and stability of an electric dune buggy will also depend on other factors, such as the suspension, tires, and weight distribution. It’s important to choose a motor that is appropriate for the specific design of the dune buggy and the type of terrain it will be driven on.

Battery and Energy Storage

Battery Types

When it comes to electric dune buggies, there are two main types of batteries to choose from: lithium-ion and lead-acid batteries. Lithium-ion batteries are lighter, smaller, and have a higher energy density than lead-acid batteries. They are also more expensive, but provide better performance and longer lifespan. On the other hand, lead-acid batteries are cheaper, but they are heavier and have a shorter lifespan.

Charging Systems

Electric dune buggies can be charged using different charging systems, including Level 1, Level 2, and DC fast charging. Level 1 charging uses a standard household outlet and can take up to 20 hours to fully charge the battery. Level 2 charging requires a special charging station and can take up to 8 hours to fully charge the battery. DC fast charging is the fastest charging option and can charge the battery up to 80% in just 15-45 minutes.

Energy Management

Managing energy is crucial for electric dune buggies to maximize their performance and range. This includes optimizing the use of regenerative braking, which converts kinetic energy into electrical energy to recharge the battery. It also involves monitoring the battery’s state of charge and temperature to avoid overcharging or overheating, which can damage the battery and reduce its lifespan. Additionally, energy management systems can be used to control the power output of the electric motor to balance performance and range.

Overall, choosing the right battery, charging system, and energy management strategy is essential for maximizing the performance and range of electric dune buggies.

Electrical Systems and Components

Controllers and Throttles

The controller is the brain of an electric dune buggy’s power system. It regulates the flow of electricity from the batteries to the motor, allowing the driver to control the vehicle’s speed and acceleration. The throttle, on the other hand, is the input device that tells the controller how much power to send to the motor.

Controllers and throttles come in a variety of shapes and sizes, but they all serve the same basic function. Some controllers are designed for high performance and can handle a lot of power, while others are more basic and are better suited for low-power applications. Throttles can be simple on/off switches or more complex devices that allow for precise speed control.

When choosing a controller and throttle for an electric dune buggy, it’s important to consider the vehicle’s power requirements and the driver’s needs. A high-performance controller may be necessary for a heavy vehicle or for off-road use, while a simple controller may be sufficient for a lightweight buggy used for casual cruising.

Wiring and Connectors

The wiring and connectors in an electric dune buggy are critical components that must be chosen carefully to ensure proper performance and safety. High-quality wiring and connectors can help prevent electrical problems, reduce the risk of fire, and improve the overall efficiency of the vehicle.

When selecting wiring and connectors, it’s important to choose components that are rated for the voltage and amperage of the vehicle’s power system. This will help ensure that the wiring and connectors can handle the electrical load without overheating or failing.

In addition to choosing the right components, it’s also important to install them correctly. Wiring should be routed away from heat sources and moving parts, and connectors should be secured and protected from moisture and vibration.

By choosing high-quality wiring and connectors and installing them correctly, an electric dune buggy can be a reliable and safe vehicle that provides years of enjoyable off-road adventures.

Cooling and Thermal Management

Electric motors generate a lot of heat, and this is especially true for high-performance motors used in dune buggies. Therefore, proper cooling and thermal management are crucial to ensure the longevity and performance of the motor.

One of the key components of a cooling system is a radiator, which dissipates heat from the motor. However, in an electric dune buggy, the cooling system must also manage the temperature of the battery pack, which can also generate significant heat.

To optimize the cooling system, some electric dune buggies use an integrated thermal management system that interconnects the coolant and refrigerant circuits. This system uses the waste heat from the electric drive efficiently for optimized energy balance. Additionally, the system integrates two electric water pumps that are controlled by a central electronics unit for the pumps and valves.

Another important aspect of thermal management is the use of heat-resistant materials for the motor and other components. This can include high-temperature insulation, cooling jackets, and heat sinks.

Maintenance and Troubleshooting

Routine Maintenance

To ensure the electric motor of the dune buggy runs smoothly, regular maintenance is essential. The following are some of the routine maintenance tasks that should be performed:

- Keep the motor clean and free of debris.

- Check the battery terminals regularly and clean them if necessary.

- Inspect the wiring and connections for any signs of wear or damage.

- Lubricate the moving parts of the motor as recommended by the manufacturer.

- Check the battery level and charge it as needed.

Performing these routine maintenance tasks will help prolong the life of the electric motor and prevent any potential issues from arising.

Common Issues and Fixes

Despite regular maintenance, issues may still arise with the electric motor of the dune buggy. Here are some common issues and fixes:

- Motor fails to start: If the motor fails to start, check the battery level and ensure it is fully charged. If the battery is not the issue, check the wiring and connections for any damage or loose connections.

- Motor runs slowly: If the motor runs slowly, check the battery level and ensure it is fully charged. If the battery is not the issue, check the wiring and connections for any damage or loose connections. It may also be necessary to lubricate the moving parts of the motor.

- Motor overheats: If the motor overheats, it may be due to a lack of ventilation or debris blocking the air vents. Clean the motor and ensure there is adequate ventilation.

- Battery fails to hold a charge: If the battery fails to hold a charge, it may be time to replace the battery. Check the manufacturer’s recommendations for the appropriate replacement battery.

By performing routine maintenance and addressing any issues promptly, the electric motor of the dune buggy can continue to run smoothly and provide an enjoyable ride.

Regulations and Safety

Legal Requirements

When it comes to electric dune buggies, it is important to note that regulations vary depending on location. Therefore, it is best to check with the local authorities to ensure that the vehicle is legal to operate on public roads. In general, electric dune buggies are subject to the same regulations as other motor vehicles, such as having a valid driver’s license, registration, and insurance.

Safety Features and Gear

Electric dune buggies must meet certain safety requirements to ensure that the vehicle is safe to operate on public roads. Some of the safety features that are required include headlights, taillights, turn signals, rearview mirrors, and seat belts. It is important to note that safety gear such as helmets and protective clothing are not only recommended but also required in some locations.

Additionally, electric dune buggies must meet certain standards for battery safety. The batteries must be securely mounted and protected from damage in the event of a collision. It is also important to ensure that the battery is not overcharged, which can lead to a fire.

Prioritize safety with an electric dune buggy. Follow legal requirements. Make sure the vehicle has necessary safety features and gear. This allows enjoying off-road thrills while minimizing accident and injury risks.