VW Dune Buggy Body: Everything You Need to Know

VW Dune Buggy Bodies are a popular choice for off-road enthusiasts and beachgoers alike. These vehicles are designed for fun and adventure, with their lightweight bodies and powerful engines providing an exciting driving experience. In this article, we will explore the history of VW Dune Buggy Bodies, the different types available, and the design and manufacturing process.

The history of VW Dune Buggy Bodies dates back to the 1960s, when Bruce Meyers created the first fiberglass dune buggy. This design was based on the Volkswagen Beetle chassis, which was modified to create a lightweight, off-road vehicle. Over the years, the design has evolved, with new features and modifications being added to improve performance and aesthetics.

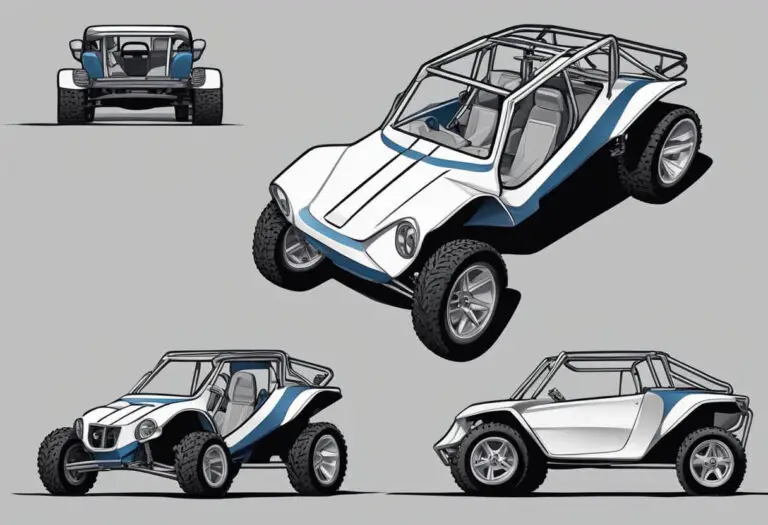

There are several different types of VW Dune Buggy Bodies available, each with its own unique features and design. Some are designed for racing, while others are more suited to casual off-road driving. They come in a range of colors and styles, from classic designs to more modern, streamlined shapes. The manufacturing process for these bodies is complex, involving the use of high-quality materials and advanced techniques to ensure durability and performance.

Key Takeaways

- VW Dune Buggy Bodies have a rich history dating back to the 1960s.

- There are several different types of VW Dune Buggy Bodies available, each with its own unique features and design.

- The manufacturing process for these bodies is complex and involves the use of high-quality materials and advanced techniques.

History of VW Dune Buggy Bodies

The Volkswagen Beetle has been the most common base for dune buggies since the 1960s. The first fiberglass dune buggy was the Meyers Manx, created by Bruce Meyers in 1964. The Meyers Manx is widely recognized as the original dune buggy and was built on the chassis of a Volkswagen Beetle. The Manx was designed to be a lightweight, high-performance vehicle that could handle the rough terrain of the desert.

The popularity of the Meyers Manx led to the creation of many other dune buggies that were built on the chassis of the Volkswagen Beetle. These buggies were typically made by modifying an existing road vehicle. The Beetle’s rear-engine design made it an ideal base for these buggies, as it provided good traction on the sand.

Over time, other vehicles were also used as a base for dune buggies. For example, the Dearborn Automobile Company (later known as Autodynamics Corporation) built the Deserter dune buggy on the chassis of a short Volkswagen floorpan and running gear. The Deserter was available in two kit-car configurations: the S1 and the GT.

Today, there are many different types of dune buggies available, but the Volkswagen Beetle remains the most popular base for these vehicles. Fiberglass dune buggy bodies are still available for purchase and can be used to build custom dune buggies. The popularity of dune buggies shows no signs of slowing down, and they remain a popular choice for off-road enthusiasts who want to explore the desert in style.

Types of VW Dune Buggy Bodies

Fiberglass Bodies

Fiberglass is the most common material used for VW dune buggy bodies. It is lightweight, durable, and easy to mold into different shapes. Fiberglass bodies come in a range of styles, from classic to modern, and are available in full-length or short-body versions. They are also customizable, allowing owners to add their own personal touches.

Metal Bodies

Metal bodies are less common than fiberglass bodies but are still available for those who prefer a more traditional look. They are typically made from steel or aluminum and are heavier than fiberglass bodies. Metal bodies are also more difficult to customize and repair.

Custom Bodies

For those who want a truly unique dune buggy, custom bodies are an option. These bodies can be made from a variety of materials, including wood, plastic, and even carbon fiber. Custom bodies are typically more expensive than fiberglass or metal bodies, but they offer the most flexibility in terms of design.

When choosing a VW dune buggy body, it is important to consider factors such as cost, durability, and personal style. Fiberglass bodies are the most popular choice due to their affordability and versatility, while metal bodies offer a more traditional look. Custom bodies are ideal for those who want a one-of-a-kind dune buggy that truly reflects their personality.

Design and Aesthetics

When it comes to the design and aesthetics of VW dune buggies, there are a few different styles and trends to consider. From classic designs to modern trends, there are plenty of options to choose from. Additionally, there are plenty of customization options available to make your dune buggy truly unique.

Classic Designs

Classic designs for VW dune buggies often feature a simple, open-air body with a minimalist aesthetic. These buggies typically have a fiberglass or aluminum body that is lightweight and easy to maneuver. Many classic designs also feature a rear-mounted engine, which provides excellent traction and handling on sandy terrain.

One popular classic design is the Meyers Manx, which was first introduced in the 1960s. This design features a distinctive, rounded body with a low profile and a minimalist interior. The Meyers Manx has become an iconic symbol of the dune buggy culture and is still popular today.

Modern Trends

In recent years, there has been a trend towards more modern and sleek designs for VW dune buggies. These buggies often feature a more streamlined body with angular lines and a more aerodynamic profile. Many modern designs also incorporate advanced technology, such as GPS navigation and Bluetooth connectivity.

One popular modern design is the Bandit dune buggy, which features a full-length fiberglass body that is both durable and lightweight. The Bandit also has a more spacious interior than many classic designs, making it a great choice for families or groups of friends.

Customization Options

One of the best things about VW dune buggies is the wide range of customization options available. Whether you want to add a custom paint job, upgrade the suspension, or install a new sound system, there are plenty of options to choose from.

Some popular customization options include:

- Custom paint jobs and decals

- Upgraded wheels and tires

- High-performance engines and transmissions

- Suspension upgrades for improved handling

- Custom interiors with premium upholstery and sound systems

Overall, the design and aesthetics of VW dune buggies offer plenty of options for customization and personalization. Whether you prefer classic designs or modern trends, there is a dune buggy out there that is perfect for you.

Manufacturing Process

Materials Used

The VW dune buggy body is typically made from fiberglass due to its lightweight and durable nature. Fiberglass is a composite material made from a combination of glass fibers and resin. The glass fibers provide the strength and stiffness while the resin acts as a bonding agent. Other materials used in the manufacturing process include gelcoat, which is applied to the mold to create a smooth surface finish, and foam, which is used to create the core of the body.

Construction Techniques

The manufacturing process for a VW dune buggy body typically involves the following steps:

- Creating a Mold: A mold is created based on the desired shape of the body. This can be done by using an existing body as a template or by designing a new shape from scratch. The mold is typically made from fiberglass or a similar material.

- Applying Gelcoat: Gelcoat is applied to the mold to create a smooth surface finish. This is important as it will be the visible surface of the body.

- Laying Fiberglass: Layers of fiberglass are then laid onto the gelcoat. The number of layers will depend on the desired strength and stiffness of the body.

- Adding Foam: Foam is added to the core of the body to provide additional strength and stiffness. This is typically done by spraying foam into the mold before the fiberglass is laid.

- Curing: The body is left to cure in the mold for a period of time. This allows the resin to harden and the body to take on its final shape.

- Removing the Body: Once the body has cured, it is removed from the mold and any excess material is trimmed away.

Overall, the manufacturing process for a VW dune buggy body is relatively straightforward and can be done with basic materials and tools. However, it does require a certain level of skill and experience to achieve a high-quality finished product.

Installation Guide

Preparation and Tools

Before starting the installation process, it is important to make sure that all the required tools and materials are available. The following tools and materials are needed for a successful installation:

- Fiberglass dune buggy body

- VW Beetle chassis

- Drill

- Rivet gun

- Silicone sealant

- Clamps

- Sandpaper

- Masking tape

- Screwdriver

- Wrench

Clean your workspace before starting installation. Remove anything that could get in the way.

Step-by-Step Installation

- First, place the fiberglass dune buggy body onto the VW Beetle chassis. Make sure that the body is properly aligned with the chassis.

- Use clamps to hold the body in place while drilling holes for the rivets. Drill holes through the body and into the chassis.

- Apply silicone sealant around the holes to prevent water from entering the body.

- Insert rivets into the holes and use a rivet gun to secure them in place.

- Once all the rivets are in place, remove the clamps and check the alignment of the body. Make any necessary adjustments before proceeding.

- Sand the edges of the body to ensure a smooth and even finish.

- Apply masking tape around the edges of the body to protect it from scratches and nicks during the installation process.

- Use a screwdriver and wrench to attach any necessary parts, such as headlights or taillights, to the body.

- Once all the parts are attached, remove the masking tape and clean the body to remove any excess debris or sealant.

By following these steps, anyone can successfully install a fiberglass dune buggy body onto a VW Beetle chassis.

Maintenance and Care

Routine Maintenance

To keep a VW dune buggy body in good condition, regular maintenance is necessary. The following are some of the routine maintenance tasks that should be performed:

- Cleaning: Regular cleaning of the body is important to prevent dirt and debris from accumulating on the surface. It is recommended to use a mild soap and water to clean the body, followed by a thorough rinse. Avoid using harsh chemicals or abrasive materials as they can damage the body.

- Waxing: Waxing the body regularly helps to protect the paint and keep it looking new. It is recommended to use a high-quality wax designed for fiberglass bodies.

- Inspecting for Damage: Regularly inspect the body for any signs of damage such as cracks, chips, or scratches. If any damage is found, it should be repaired immediately to prevent it from getting worse.

Repair and Restoration

Over time, a VW dune buggy body may require repairs or restoration. The following are some of the repair and restoration tasks that may be necessary:

- Fiberglass Repair: Fiberglass bodies are prone to cracking and chipping. If any damage is found, it can usually be repaired with fiberglass repair kits. These kits contain everything needed to repair small cracks and chips.

- Paint Repair: If the paint on the body is damaged, it may be necessary to repaint the body. This can be done by sanding down the damaged area, applying primer, and then applying a new coat of paint.

- Replacement Parts: If any parts of the body are damaged beyond repair, they may need to be replaced. Replacement parts can be purchased from a variety of sources, including online retailers and specialty shops.

By following these routine maintenance and repair tasks, a VW dune buggy body can be kept in good condition for years to come.

Performance and Safety

Enhancing Performance

When it comes to enhancing the performance of a VW Dune Buggy Body, there are a few things to consider. One of the most important factors is the engine. Upgrading the engine can significantly improve the buggy’s speed and overall performance. A popular engine upgrade is the installation of a high-performance air-cooled engine, which can increase horsepower and torque.

Another way to enhance the performance of a VW Dune Buggy Body is by upgrading the suspension system. A high-performance suspension system can provide better handling and stability, especially when driving off-road. Additionally, upgrading the brakes can improve stopping power and reduce the risk of accidents.

Safety Features

Safety is of utmost importance when it comes to driving a VW Dune Buggy Body. Fortunately, there are several safety features that can be added to improve the safety of the vehicle. One important safety feature is the installation of a roll cage. A roll cage can protect the driver and passengers in the event of a rollover accident.

Another important safety feature is the installation of a seat belt. Seat belts can prevent passengers from being ejected from the vehicle in the event of an accident. Additionally, installing a windshield can provide protection from debris and other hazards while driving.

Legal Considerations

Street Legality

When it comes to street legality, it is important to check the regulations in your state or country. In the United States, the laws vary by state, but generally, dune buggies are not considered street legal vehicles. However, some states may allow dune buggies to be registered as kit cars or special construction vehicles. In these cases, the dune buggy must meet certain safety requirements such as having seat belts, headlights, turn signals, and other safety features.

Off-Road Regulations

Off-road regulations also vary by location. In general, dune buggies are designed for off-road use and are not subject to the same regulations as street legal vehicles. However, it is important to check the regulations in your area before taking your dune buggy off-road. Some areas may require permits or have restrictions on where off-road vehicles can be operated. It is also important to consider safety when operating a dune buggy off-road. Always wear safety gear such as helmets and protective clothing, and follow safe driving practices to avoid accidents.

Overall, it is important to be aware of the legal considerations when owning and operating a dune buggy. By following the regulations and safety guidelines, you can enjoy your dune buggy while staying safe and avoiding legal issues.