VW Dune Buggy Wiring Harness: A Comprehensive Guide

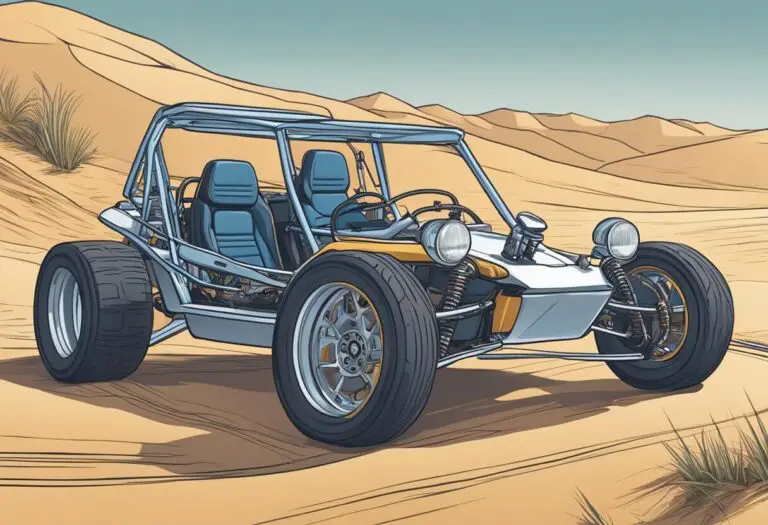

A VW dune buggy wiring harness is a crucial component of any off-road vehicle. It provides the electrical connections necessary to power everything from the engine to the headlights and taillights. Without a properly functioning wiring harness, a dune buggy is little more than a collection of parts.

There are several different types of VW dune buggy wiring harnesses available on the market today. Some are designed specifically for use with certain types of engines, while others are more universal in nature. It is important to choose the right harness for your particular vehicle to ensure that it will function properly and provide reliable electrical connections.

When shopping for a VW dune buggy wiring harness, it is important to consider factors such as the quality of the components, the ease of installation, and the level of documentation provided. Some harnesses come with detailed instructions and wiring diagrams, while others may require more experience and expertise to install properly. Ultimately, the right wiring harness will depend on your specific needs and the type of vehicle you are working with.

Understanding VW Dune Buggy Wiring Harnesses

When it comes to building or restoring a VW dune buggy, one of the essential components that should not be overlooked is the wiring harness. A wiring harness is a collection of wires and connectors that are used to transmit electrical power and signals to various components of the buggy.

Components of a Wiring Harness

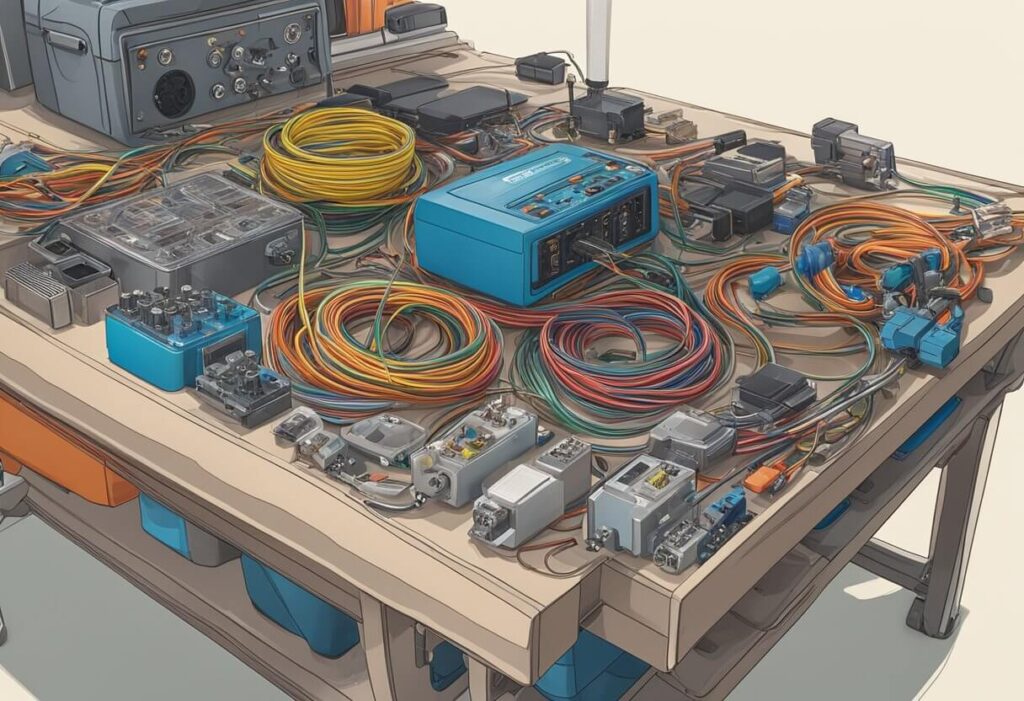

A typical VW dune buggy wiring harness consists of several components that work together to ensure reliable electrical connections. Some of the common components of a wiring harness include:

- Wires: These are the conductive pathways that transmit electrical power and signals between the different components of the buggy.

- Connectors: These are the devices that are used to connect the wires to the various components of the buggy. Connectors come in different shapes and sizes, and they are designed to fit specific components.

- Fuses: These are the safety devices that protect the electrical system from overloading and short circuits. Fuses are designed to break the circuit when the current exceeds a certain limit, preventing damage to the electrical system.

Types of VW Dune Buggy Wiring Kits

There are different types of VW dune buggy wiring kits available in the market, each designed to meet specific needs and requirements. Some of the common types of wiring kits include:

- Universal Wiring Kits: These are the most common type of wiring kits, and they are designed to fit most VW dune buggies. Universal wiring kits come with a detailed wiring diagram, connectors, fuses, and other necessary components.

- Custom Wiring Kits: These are the wiring kits that are designed to meet specific needs and requirements. Custom wiring kits are usually more expensive than universal wiring kits, but they offer more flexibility and customization options.

In summary, a VW dune buggy wiring harness is an essential component that should not be overlooked when building or restoring a buggy. Understanding the different components and types of wiring kits available can help you choose the right wiring harness for your specific needs.

Installation Basics

Tools Required for Installation

Before starting the installation process, it is important to gather all the necessary tools. The following tools are required for a successful installation of the VW dune buggy wiring harness:

- Wire cutters/strippers

- Crimping tool

- Electrical tape

- Screwdriver set

- Socket set

- Wire connectors

- Heat shrink tubing

- Test light

Preparing the Dune Buggy for Wiring

Before installing the wiring harness, it is important to prepare the dune buggy. The first step is to remove the old wiring harness and any unnecessary components. This will make the installation process easier and ensure that the new wiring harness is not cluttered.

Next, inspect the dune buggy’s electrical system and ensure that all components are in good working condition. This includes the battery, alternator/generator, starter, ignition switch, and all lights and accessories.

Step-by-Step Installation Process

The following is a step-by-step guide to installing the VW dune buggy wiring harness:

- Lay out the wiring harness and familiarize yourself with its components and connections.

- Install the fuse box and connect the positive and negative battery cables.

- Connect the ignition switch, starter, and alternator/generator wires.

- Install the headlight and taillight wiring.

- Connect the turn signal and brake light wiring.

- Install the accessory wiring, including the radio, gauges, and any other electrical components.

- Test the wiring harness using a test light and ensure that all connections are secure and functioning properly.

By following these steps and using the necessary tools, the installation of the VW dune buggy wiring harness can be completed efficiently and successfully.

Electrical System Configuration

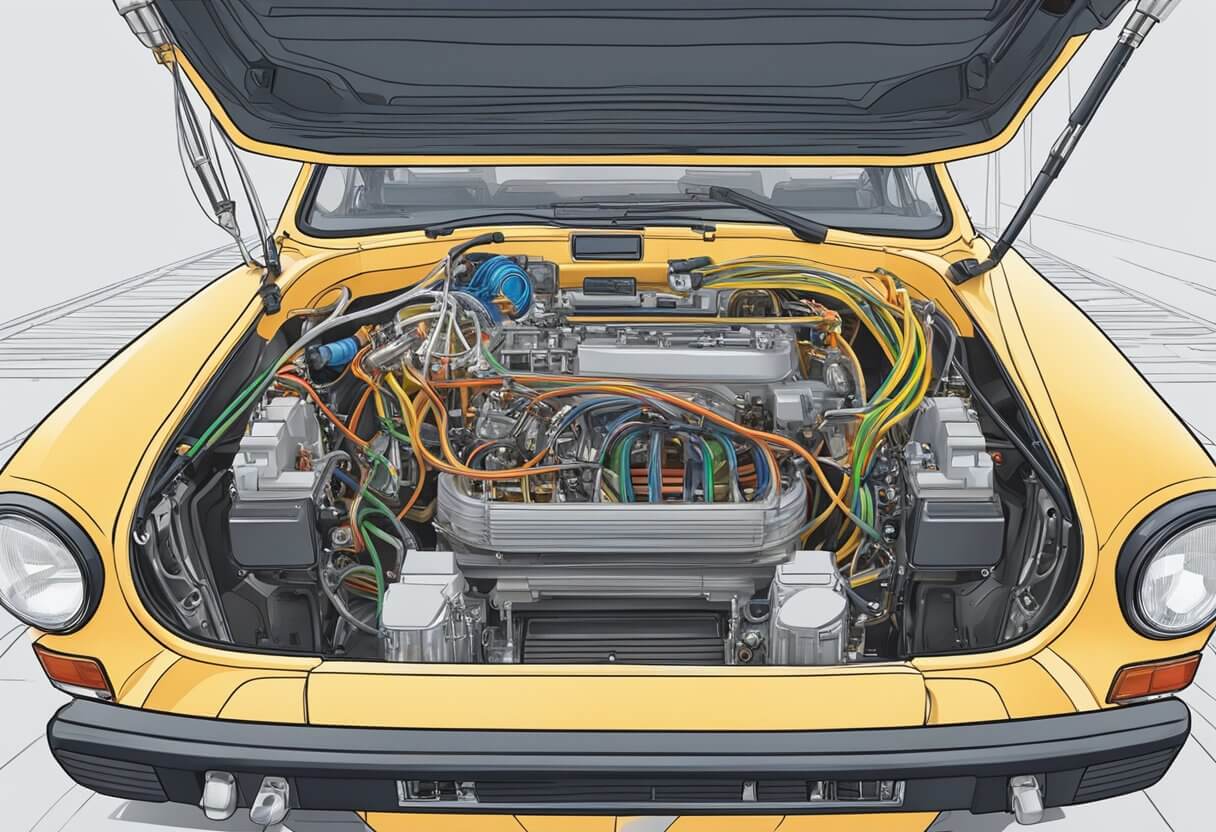

When it comes to installing a VW dune buggy wiring harness, it is important to understand the electrical system configuration. This includes the wiring diagrams and schematics, as well as customizing the electrical layout to fit the specific needs of the vehicle.

Wiring Diagrams and Schematics

Wiring diagrams and schematics are essential tools for any electrical installation. They provide a visual representation of the electrical system and help ensure that all components are properly connected. When installing a VW dune buggy wiring harness, it is important to have a wiring diagram or schematic that is specific to the make and model of the vehicle.

A wiring diagram will show the location of each wire, the color of the wire, and the function of each wire. This information is essential for proper installation and troubleshooting. A schematic, on the other hand, will show the electrical components and how they are connected. This is useful for understanding the overall electrical system configuration.

Customizing the Electrical Layout

Customizing the electrical layout of a dune buggy is important for ensuring that all components are properly connected and that the electrical system is efficient. This can include adding additional lighting, sound systems, or other electrical components.

When customizing the electrical layout, it is important to consider the power requirements of each component and ensure that the wiring and electrical system can handle the load. It is also important to ensure that all wiring is properly insulated and protected from damage.

Overall, understanding the electrical system configuration of a VW dune buggy wiring harness is essential for proper installation and customization. Wiring diagrams and schematics are important tools for ensuring that all components are properly connected, and customizing the electrical layout can help ensure that the electrical system is efficient and meets the specific needs of the vehicle.

Troubleshooting Common Issues

Identifying Wiring Problems

When it comes to troubleshooting wiring issues in a VW dune buggy, it’s important to start by identifying the problem. Some common signs of wiring problems include:

- Flickering or dimming lights

- Non-functioning gauges or accessories

- Blown fuses

- Burning smells or smoke

If you notice any of these signs, it’s important to inspect the wiring harness for any visible damage. Look for frayed wires, loose connections, or signs of burning or melting. It’s also a good idea to use a multimeter to check for continuity and voltage throughout the wiring system.

Repairing or Replacing Faulty Wires

Once you’ve identified the problem, the next step is to repair or replace any faulty wires. In some cases, this may involve splicing in a new section of wire or replacing a connector. In other cases, it may be necessary to replace the entire wiring harness.

When repairing or replacing wiring, it’s important to use high-quality materials and follow the manufacturer’s instructions carefully. This will help ensure that the wiring system is safe, reliable, and free from future problems.

In conclusion, troubleshooting wiring issues in a VW dune buggy can be a challenging task. However, by identifying the problem and taking the necessary steps to repair or replace any faulty wires, it’s possible to keep your buggy running smoothly and safely for years to come.

Maintenance and Care

Routine Checkups

To ensure the longevity and reliability of your VW dune buggy wiring harness, routine checkups are necessary. This involves inspecting the harness for any signs of wear and tear, such as frayed wires or loose connections. The frequency of these checkups will depend on the frequency of use and the intensity of off-road adventures. However, it is recommended to perform a checkup at least once every six months.

During the checkup, it is important to inspect the harness for any signs of damage or corrosion. Any damaged or corroded wires should be replaced immediately. Additionally, it is recommended to clean the harness with a dry cloth to remove any dirt or debris that may have accumulated.

Long-Term Harness Preservation

In addition to routine checkups, long-term harness preservation is also important. This involves taking measures to protect the harness from extreme weather conditions and other environmental factors that may cause damage. For example, storing the buggy in a covered area when not in use can help prevent exposure to moisture and UV rays.

It is also important to use high-quality components when repairing or replacing parts of the harness. This will ensure that the harness remains durable and reliable over time. Additionally, using protective covers or sleeves for the wires can help prevent damage from rocks and other debris that may be encountered during off-road adventures.

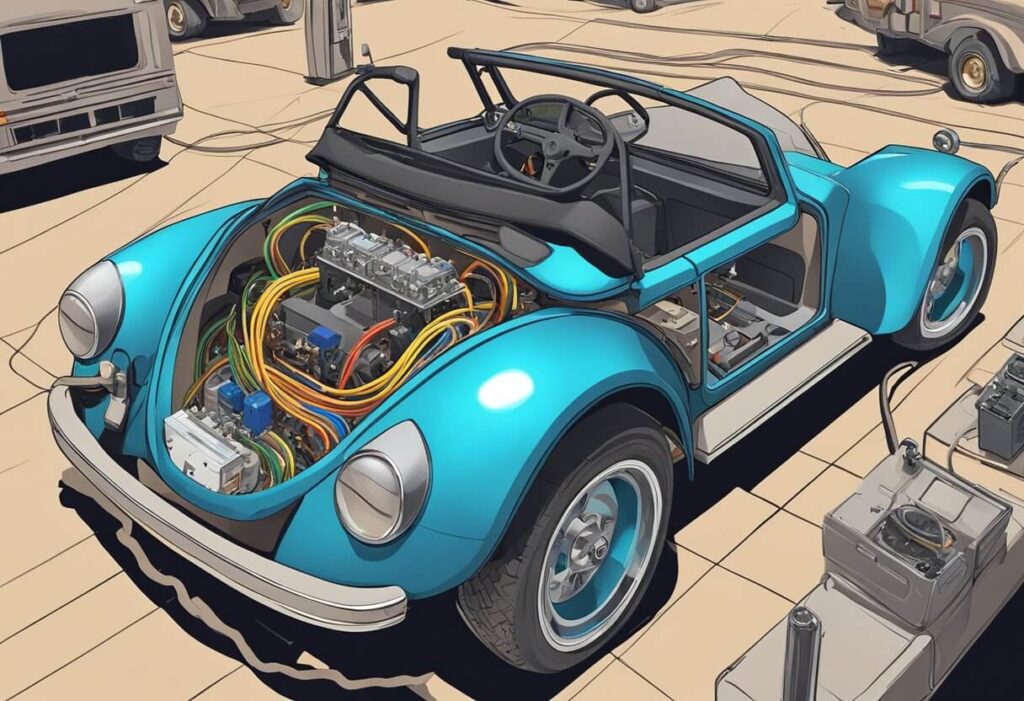

Upgrades and Modifications

Enhancing Performance with Upgraded Wiring

Upgrading the wiring harness in a VW dune buggy can improve the performance of the vehicle by ensuring that the electrical components are receiving the necessary power and signal. A high-quality wiring harness can prevent electrical issues such as shorts, voltage drops, and overheating.

One option for upgrading the wiring harness is to install a harness kit that is specifically designed for dune buggies. These kits often include a detailed wiring diagram for all common accessories and engine items, a fuse box with OE VW style fuses, connectors, and electric tape. Another option is to install a custom wiring harness that is tailored to the specific needs of the vehicle. This can be a more expensive option, but it allows for greater flexibility and customization.

Incorporating Additional Electrical Accessories

Dune buggy enthusiasts often want to incorporate additional electrical accessories into their vehicles, such as off-road lights, sound systems, and GPS devices. Adding these accessories can put a strain on the existing wiring harness and can lead to electrical issues if not properly installed.

To incorporate additional electrical accessories, it is important to ensure that the wiring harness is capable of handling the additional load. Upgrading the alternator and battery can also help to provide the necessary power. It is recommended to use a relay for each accessory to prevent overloading the existing wiring harness.

When installing additional electrical accessories, it is important to follow the manufacturer’s instructions and to use high-quality components. It is also important to properly ground each accessory to prevent electrical issues.

Frequently Asked Questions

How can I replace a wiring harness in my VW dune buggy?

Replacing a wiring harness in a VW dune buggy involves disconnecting the old wiring harness and installing a new one. It is important to ensure that the new wiring harness is compatible with the make and model of the dune buggy. It is recommended to seek professional help for this task if you are not familiar with automotive wiring.

Where can I find a wiring diagram for installing a new harness in a dune buggy?

Wiring diagrams for installing a new harness in a dune buggy can be found online or in the instruction manual that comes with the new harness. It is important to follow the wiring diagram carefully to avoid any electrical issues.

What are the differences between an Empi wiring harness and a Rebel wiring harness?

Empi and Rebel are two popular brands of wiring harnesses for dune buggies. While both brands offer high-quality wiring harnesses, there are some differences. Empi wiring harnesses are known for their detailed wiring diagrams and OE VW style fuses. Rebel wiring harnesses, on the other hand, are known for their affordability and simplicity.

What should be included in a complete wire harness kit for a dune buggy?

A complete wire harness kit for a dune buggy should include all the necessary wires, connectors, and fuses needed for the electrical system. It should also come with a detailed wiring diagram for easy installation.

How can I diagnose a faulty wiring harness in my vehicle?

A faulty wiring harness can cause various electrical issues in a dune buggy, including malfunctioning lights, engine failure, and a dead battery. To diagnose a faulty wiring harness, it is recommended to check the wires and connectors for any signs of damage or corrosion. A multimeter can also be used to test the electrical continuity of the wires.

What are common reasons for wiring harness failures in dune buggies?

Common reasons for wiring harness failures in dune buggies include exposure to moisture, wear and tear, and overheating. It is important to regularly inspect the wiring harness and address any issues as soon as possible to avoid further damage.